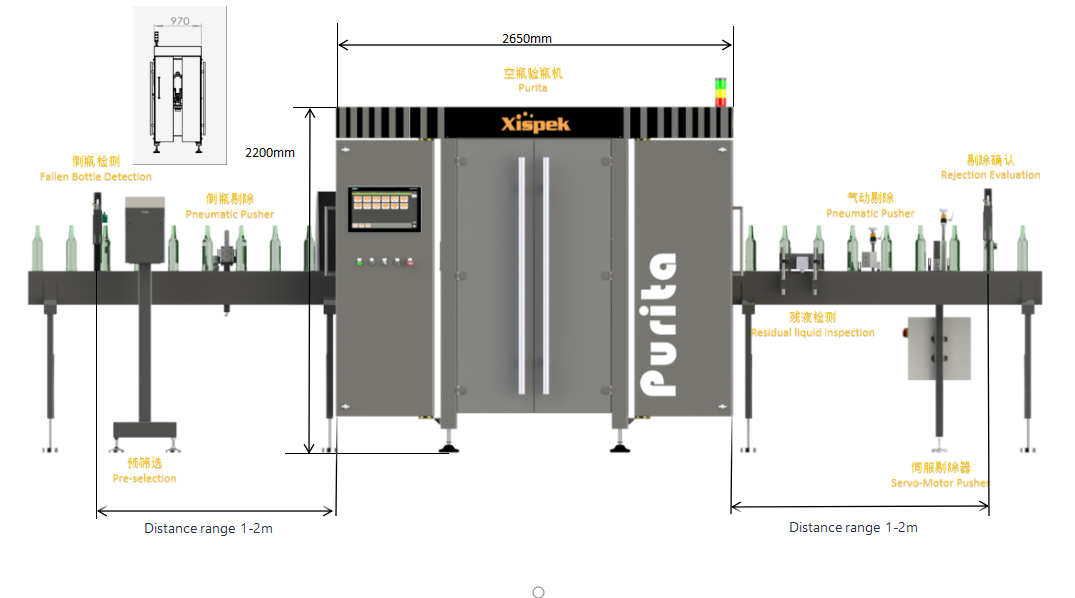

The empty bottle inspection machine is the most critical inspection equipment in all beer glass bottle production lines. It is an essential inspection device for both new and recycled beer bottles. Xispek's Purita empty bottle inspection system is a linear inspection equipment that integrates comprehensive detection functions for the bottle mouth, body, and base. It ensures that empty beer bottles meet filling production standards before packaging, thereby reducing customer complaints.

|

Scope of application:

|

Installation position:

|

Empty Bottle Inspector Purita is an all-in-one inspection device integrating comprehensive empty bottle detection functions.Equipment dimension 2650*970*2200mm (length*width*height), with a maximum inspection capacity of 60,000 bottles/hour.

Before entering the Purita inspection system, glass bottles pass through the sensor-based pre-selection module Selecta S (or the optional CCD-based pre-selection module Selecta G) to reject wrong bottles.This prevents non-compliant bottles from entering the production line, enhancing production quality and protecting the equipment from damage.

The bottle outside wall inspection function of the Purita machine employs polarized light and specular reflection designs to achieve maximum viewing angles and the best image quality.By scanning and analyzing the entire bottle body, it can rapidly and accurately detect dirt, foreign objects, or other defects adhering to the bottle walls

For finish inspection, Purita utilizes high-resolution cameras to precisely examine bottle finish..Ensure inspection breakage, defects, or other abnormalities are detected, the system ensures product quality and safety.

The base inspection function enhances precision by combining backlighting and specialized optical lenses to expand the visible area. Additionally, the Purita machine includes a residual lye detection module, capable of identifying even trace amounts of lye.

Optional modules such as inner wall inspection and thread inspection can be added to achieve full-coverage detection for bottles with varying transparency levels or intricate body patterns.

Sensor-based Selecta S

Sensor-based Selecta S

Selecta S is equipped with three

photoelectric sensors that detect tall bottles, short bottles, and fallen bottles by identifying the shape and height of the bottle.

CCD camera-based Selecta G (Optional)

CCD camera-based Selecta G (Optional)

The Selecta G utilizes a CCD camera to

precisely identify bottle height, color, and shape, ensuring no wrong bottles enter the production line.

Rejection System

Rejection System

After the pre-selection system, a pneumatic pusher is installed before the empty bottle inspection machine to reject unqualified bottles into the rejection bin, so as to avoid any damage to the inspection machine.

Outer Sidewall Inspection

Outer Sidewall Inspection

Finish

Inspection

Finish

Inspection

Top

thread inspection(Optional)

Top

thread inspection(Optional)

Base

Inspection

Base

Inspection

Inside

Sidewall inspection(Optional)

Inside

Sidewall inspection(Optional)

Residual

Liquid Inspection

Residual

Liquid Inspection

Test

Bottle Program

Test

Bottle Program

Rejection

Rejection

The system primarily detects foreign materials adhering to bottle walls, such as transparent tape, cigarette ash, etc.

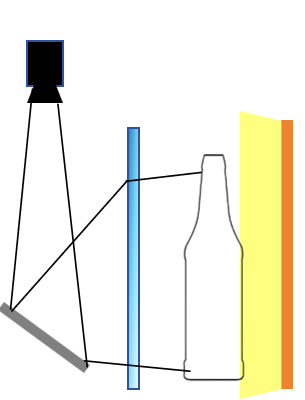

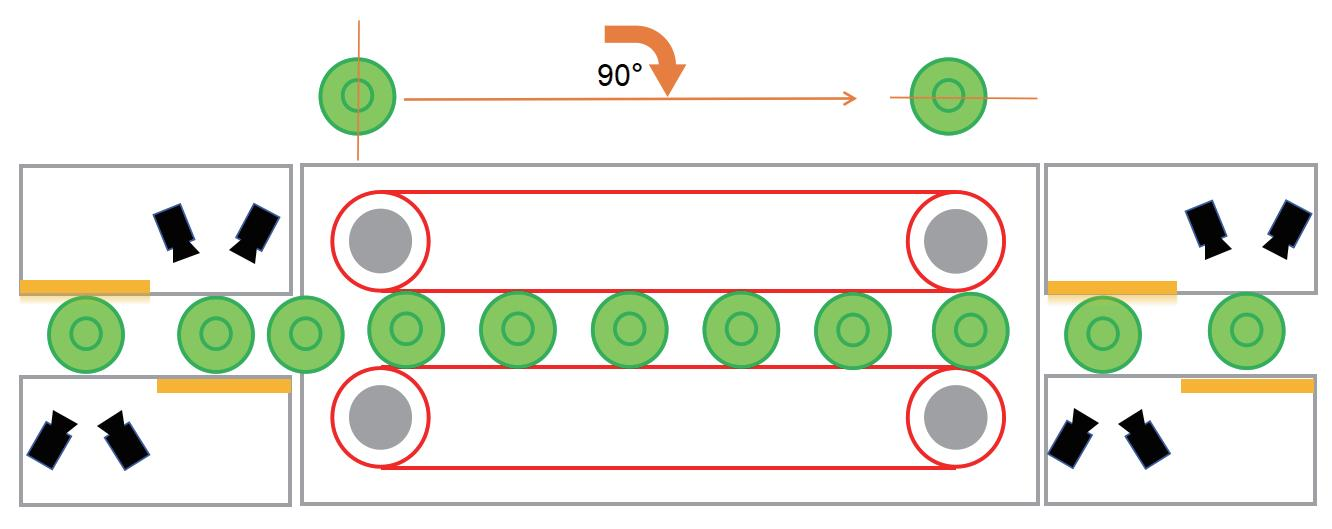

The exterior inspection utilizes a total of

8 cameras arranged in four inspection modules at both the infeed and outfeed

ends. After initial inspection at the infeed end, the bottles are rotated 90

degrees through differential speed control of two clamping motors before

undergoing final inspection at the outfeed end. This dual-phase inspection

achieves 720° full-coverage detection of the bottle surface.

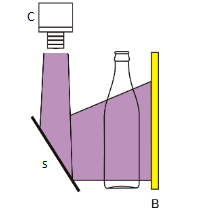

Each inspection module features a uniquely

designed camera configuration with polarized light sources and polarized

lenses. This optical system eliminates scattered light interference and

enhances image contrast, enabling reliable detection of transparent and

semi-transparent contaminants. The technology effectively compensates for

challenging bottle structures, including uneven glass thickness and embossed

patterns, ensuring consistent imaging quality.

In standard operation, defective bottles

are typically returned to the bottle washer for reprocessing. The secondary

rejector at the outfeed end transfers these bottles to a rejection platform,

from where they are conveyed back to the washing system.

Outer Sidewall Inspection Features:

High-intensity LED lighting enables

reliable detection on dark-colored bottles.

High-intensity LED lighting enables

reliable detection on dark-colored bottles.

Polarized

filters enhance identification of transparent/semi-transparent foreign

materials.

Polarized

filters enhance identification of transparent/semi-transparent foreign

materials.

Automatic jam alarm with safety doors on

both infeed/outfeed sides for easy blockage clearance.

Automatic jam alarm with safety doors on

both infeed/outfeed sides for easy blockage clearance.

Removable double-layer glass design for

each exterior inspection module, ensuring durability and maintenance

efficiency.

Removable double-layer glass design for

each exterior inspection module, ensuring durability and maintenance

efficiency.

Primarily inspects surface contaminants, cracks, chips, and other defects on the bottle finish (mouth) .

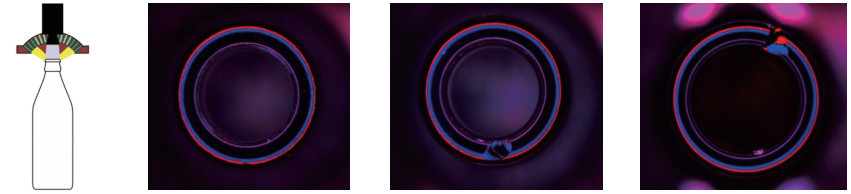

Utilizes a high-speed color industrial

camera paired with a custom multi-channel LED strobe light and an independent

photoelectric trigger sensor.

Features a vertical illumination design where the top light source and camera align perpendicularly with the bottle base, ensuring precise capture of minute defects across inner, outer, and intermediate zones of the finish.

Bottles flagged as defective by the finish

inspection module are immediately ejected by the primary rejector into a waste

container, as they hold no salvage value.

The bottle mouth inspection system features the following characteristics:

Utilizes high-speed color industrial

cameras

Utilizes high-speed color industrial

cameras

Incorporates independent trigger sensors

Incorporates independent trigger sensors

Employs different color LED light sources

for various bottle mouth types

Employs different color LED light sources

for various bottle mouth types

Offers adjustable height to accommodate

different SKUs

Offers adjustable height to accommodate

different SKUs

The system primarily detects defects in the

bottle mouth threads.

Integrated within the same module as the bottle wall inspection, it conducts thread detection at both the bottle entry and exit ends. After inspection at the entry end, the clamped bottle is rotated 90 degrees via the differential speed of two drive motors gripping the bottle. The thread is then re-inspected at the exit end, enabling photo coverage of 720° (full 360° coverage) around the bottle mouth threads. This dual-point inspection aims to mitigate imaging inaccuracies caused by uneven glass thickness or variations in thread shape, ensuring more reliable detection.

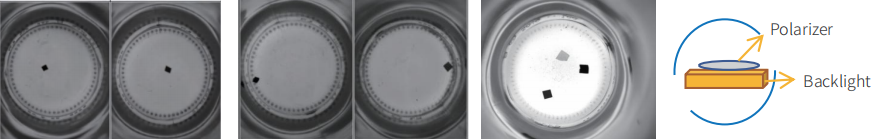

The system primarily detects dirt and

foreign materials at the bottle bottom, such as transparent cigarette packaging

film or cigarette butts.

It employs specialized lens imaging

technology paired with custom-designed optical lenses to enhance the visible

area of the bottle bottom. By analyzing

grayscale variations across different regions of the captured image, the system

determines whether the bottle bottom meets standards. Additionally, a polarizing filter is

integrated to detect transparent materials like cigarette film. A trigger sensor is installed at the module’s

front to precisely control the image-capturing timing. A brush and an automatic air-blowing device

are also equipped to remove residual water under bottle after washing, eliminating

interference during inspection.

Under normal conditions, bottles identified

as contaminated by the bottom inspection module are rejected by a second

ejector.The ejector removes non-compliant bottles to a rejection platform,

after which they are conveyed back to the bottle washer for re-cleaning.

Bottle Bottom Inspection Features:

Utilizes customized brushes + air-blow

system to ensure clear imaging

Utilizes customized brushes + air-blow

system to ensure clear imaging

Incorporates polarizing filters for

enhanced detection of transparent/semi-transparent contaminants

Incorporates polarizing filters for

enhanced detection of transparent/semi-transparent contaminants

Features an easily detachable and

replaceable outer structure with dual-light-source protection design

Features an easily detachable and

replaceable outer structure with dual-light-source protection design

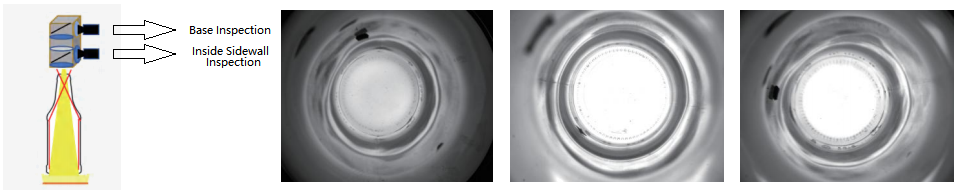

Primary Detection Targets: Focuses on

identifying foreign materials and contaminants on the inner wall of bottles.

The system utilizes an industrial camera combined with a concave-convex lens for imaging. In external wall inspection, factors such as patterns, designs on the bottle wall, or wear rings on recycled bottles may affect detection accuracy. The addition of internal wall inspection effectively addresses this issue, providing an extra layer of assurance for bottle inspection and ensuring detection quality.

Primarily identifies residual liquids

inside bottles, including alkaline solutions and water.

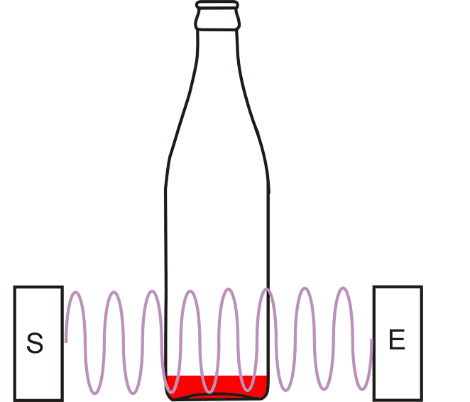

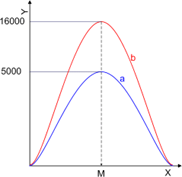

The detection of residual alkaline solution adopts the high-frequency electromagnetic field principle. The high-frequency sensor consists of a transmitter head and a receiver head, which are installed on opposite sides of the conveyor belt. The recorded measurements can be displayed in the form of waveform curves, effectively detecting water residues exceeding 4mm above the bottle bottom and alkaline solutions exceeding 1ml.

Under normal circumstances, bottles

defective due to residual alkaline solution can be sent back to the bottle

washer for recleaning. Therefore, in most cases, the secondary ejector removes

them to the rejection platform, after which they are conveyed back to the

bottle washing machine for reprocessing.

The residual liquid detection system features the following characteristics:

An intelligent signal processing system for

accurate identification of water and alkaline solutions

An intelligent signal processing system for

accurate identification of water and alkaline solutions

A closed-loop quality control system that

uses dedicated ejectors to remove defective bottles to a platform, where they

are conveyed back to the bottle washer for recleaning

A closed-loop quality control system that

uses dedicated ejectors to remove defective bottles to a platform, where they

are conveyed back to the bottle washer for recleaning

The test bottle program employs a timed self-check reminder mechanism. During specified production cycles (time-based or quantity-based), a predetermined number of defective bottles are introduced. The system performs intelligent comparison between preset defect quantities and actual measured data, automatically generating visual comparison reports with deviation analysis.

The system features a smart alert mechanism that triggers tiered alarms when inspections are not executed or anomalies are detected (audible/visual alert → production line speed reduction → emergency shutdown). Administrators can monitor detection data in real-time to ensure inspection accuracy, minimize production losses, and maintain continuous, stable operation of the production line.

The Purita standard configuration includes three rejectors. The first pneumatic rejector is installed after the irregular bottle pre-sorting module to reject and scrap malformed bottles. The second pneumatic rejector is mounted on the single-lane conveyor at the Purita inspection machine's exit, which removes bottles with defective bottle mouths or threads into a scrap bin. The third servo-controlled rejector is positioned at the Purita inspection machine's exit, specifically designed to reject bottles contaminated with wall defects, base defects, or residual alkali solutions, sending them for unified recycling and cleaning.