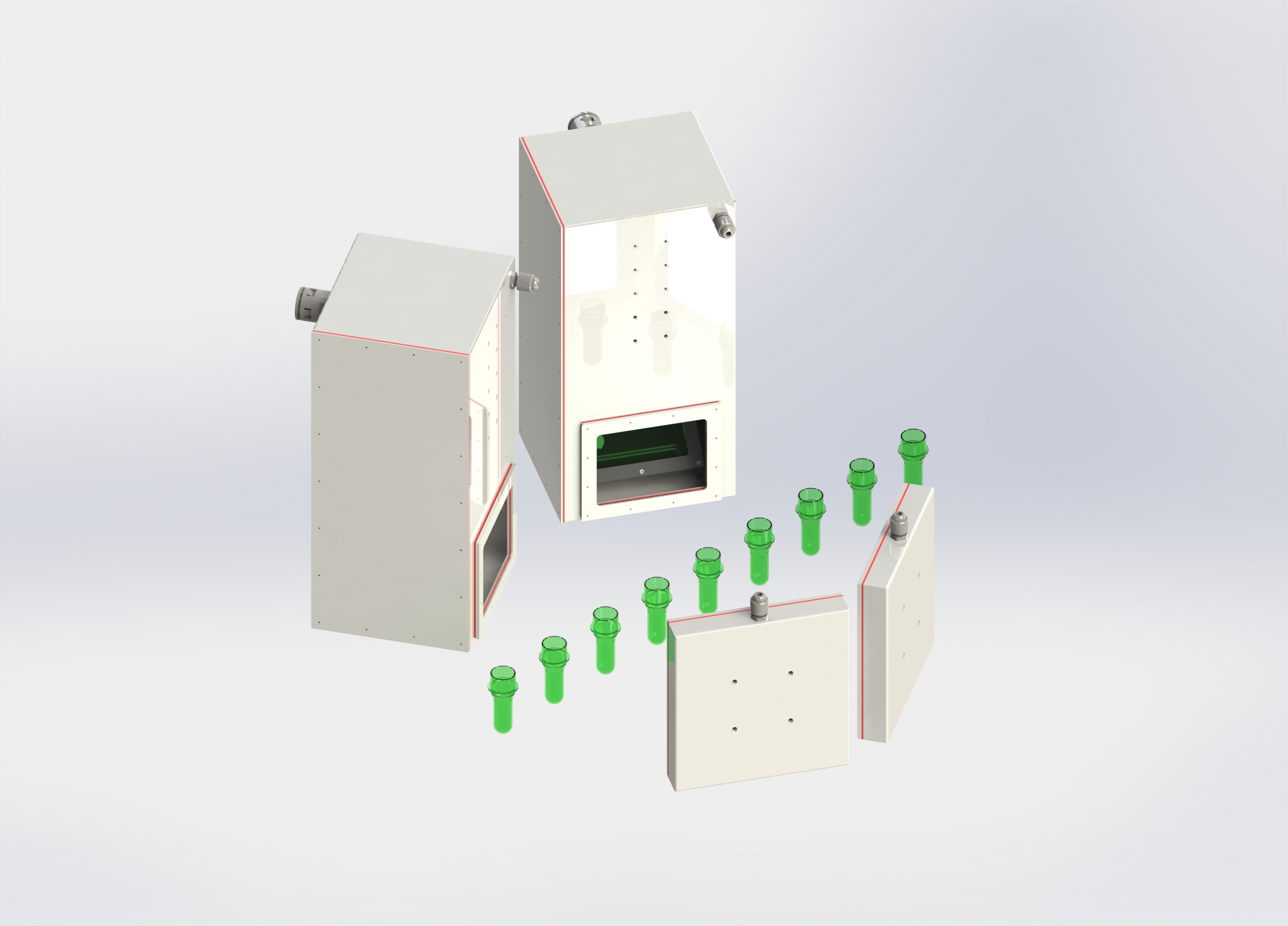

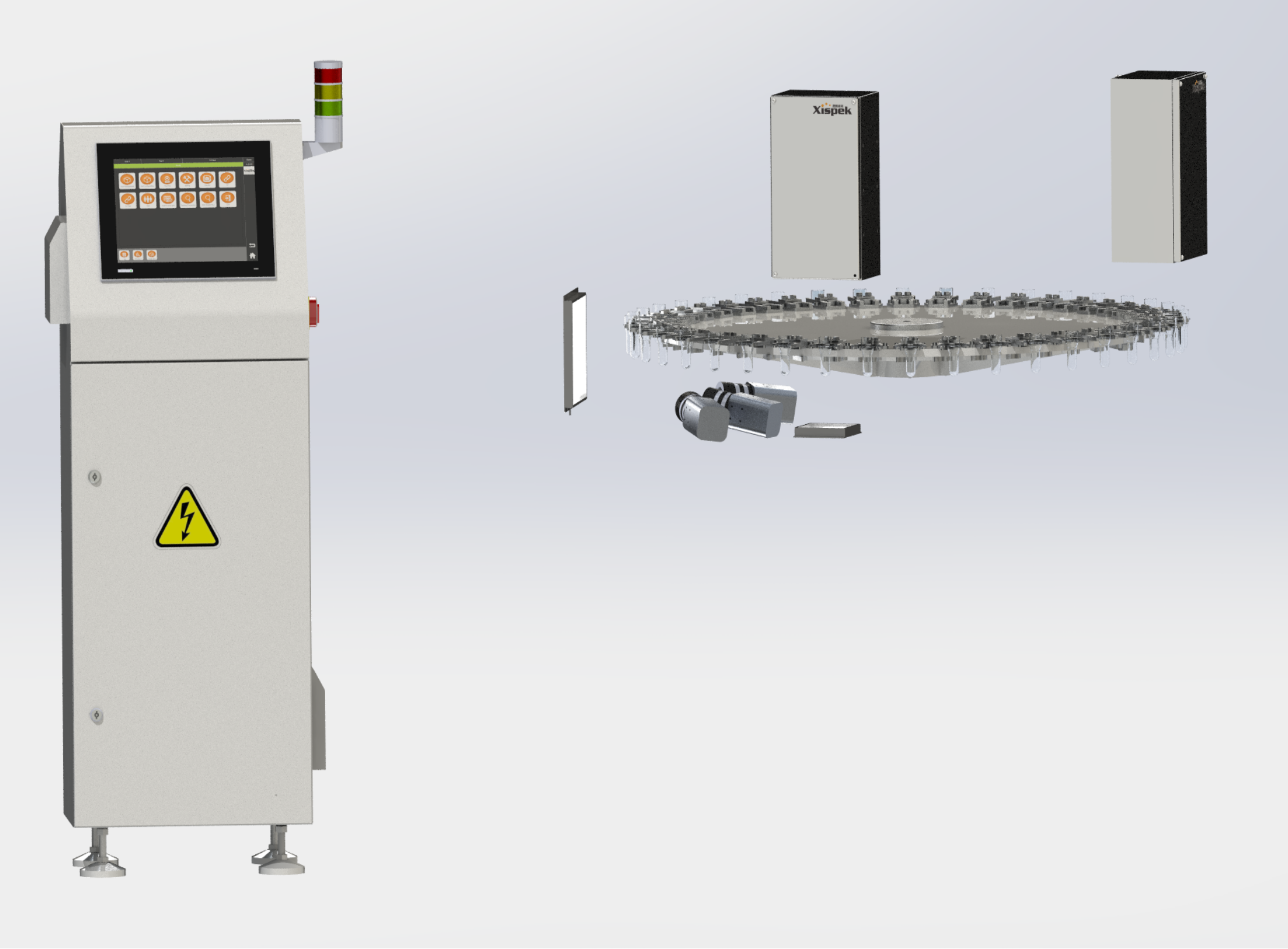

The preform inspection module is installed inside the blow molder of the PET production line, utilizing high-quality industrial cameras and maintenance-free LED lighting. It consists of two modular inspection units for the finish and body of preforms, which can be flexibly configured as needed.

|

Scope of application:

|

Installation position:

|

The preform inspection system is installed at the preform feed inlet/mid-section of the heating zone. Its compact modular design enables integration into blow molders of various sizes. The system consists of two inspection modules for the finish (neck) and body of preforms. Different control centers can be selected based on production line speeds, achieving a maximum inspection capacity of 72,000 preforms per hour.

Preform Finish:Notches, Dimensions, Roundness,

Scratches

Preform Finish:Notches, Dimensions, Roundness,

Scratches

Preform Body: Cracks/Breakage, Contamination,

Color Deviation, Deformation

Preform Body: Cracks/Breakage, Contamination,

Color Deviation, Deformation

Compact design for easy integration into blow molders

Compact design for easy integration into blow molders

Inspection modules with IP65 rating for harsh environment adaptation

Inspection modules with IP65 rating for harsh environment adaptation

Configurable options per customer requirements, compatible with auxiliary modules (e.g., empty bottle inspection) for multifunctional inspection

Configurable options per customer requirements, compatible with auxiliary modules (e.g., empty bottle inspection) for multifunctional inspection