The bottle cap inspection machine is used in PET production lines to inspect cap defects before filling, preventing defective caps from causing filling machine stoppages during subsequent processes.

Scope of application: PET cap PET cap |

Installation position: Before filling machine Before filling machine |

The bottle cap inspection system achieves a maximum throughput of 72,000 caps per hour.

The inspection process utilizes one color industrial camera to examine cap appearance characteristics. The system is installed on the vacuum conveyor belt preceding the filler, eliminating potential inspection interference caused by cap slippage during transportation. Following inspection, defective caps are rejected through a pneumatic pusher.

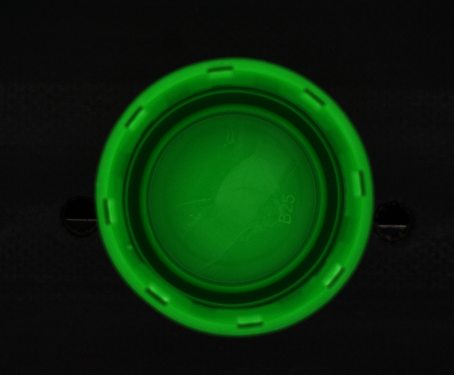

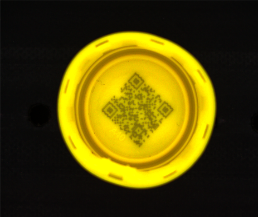

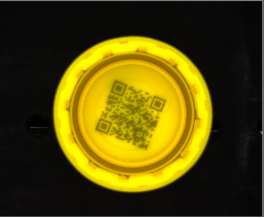

Wrong cap

Wrong cap Oval cap

Oval cap Incorrect Size

Incorrect Size Rolled edge

Rolled edge

Dirty

Dirty

|

|

|

|

Wrong cap |

Oval cap |

Rolled edge |

|

|

|

|

Dirty |

|

|

Installed on the vacuum conveyor belt to prevent cap slippage from affecting inspection accuracy.

Installed on the vacuum conveyor belt to prevent cap slippage from affecting inspection accuracy.

Adopts XispVision® Universal Inspection Software Platform

Adopts XispVision® Universal Inspection Software Platform

High inspection efficiency and inspection accuracy

High inspection efficiency and inspection accuracy

Compact design for easy integration

Compact design for easy integration

IP65 protection level for various environment

IP65 protection level for various environment