Pentra Can is an economical all-in-one inspection machine. It can be installed after the filling machine or after the pasteurizer. Pentra Can utilizes X-ray fill level inspection and sensor for uncovered products.

|

Scope of application:

|

Installation position:

|

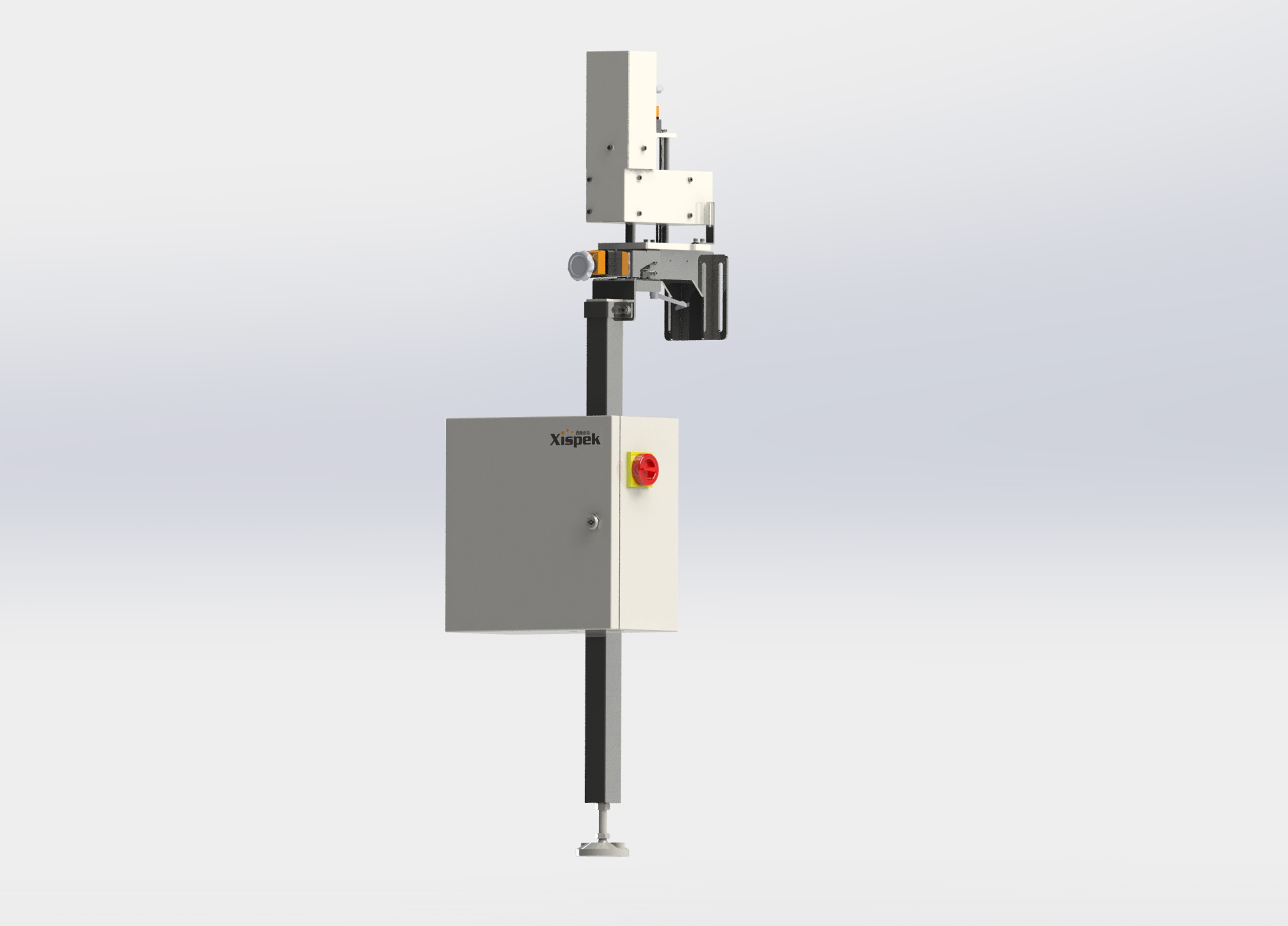

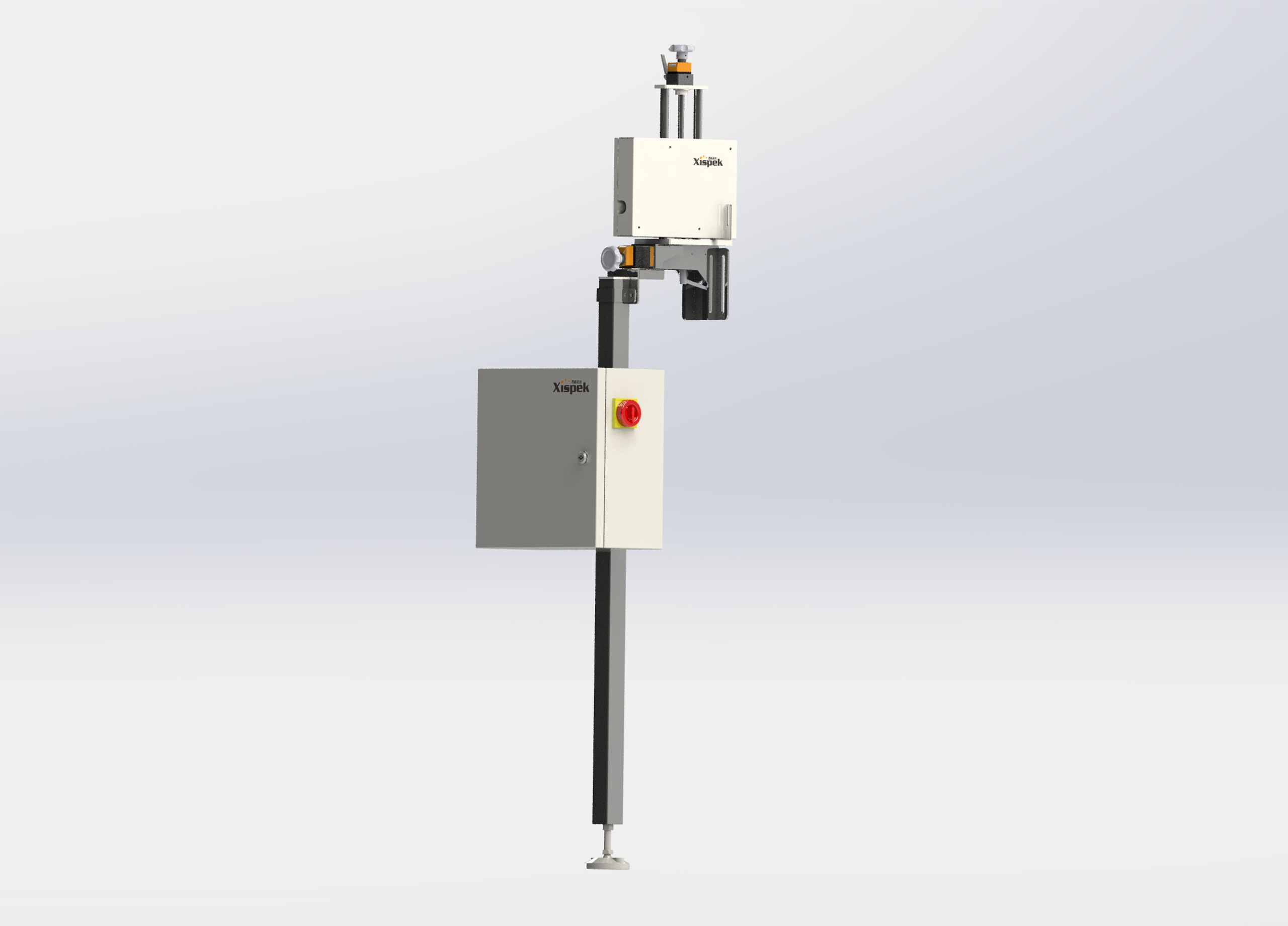

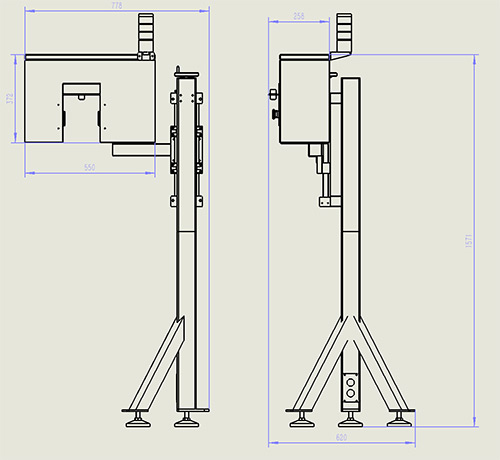

Pentra is an economical, integrated full-can inspection system specifically designed for beverage can production lines. With compact dimensions of 778*620*1571mm (LWH), it delivers maximum inspection capacity of 72,000 cans/hour.

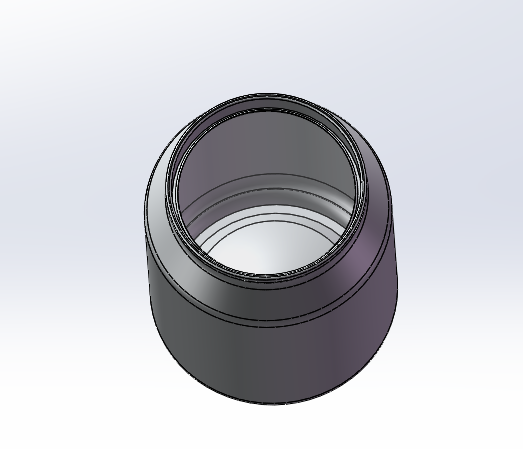

Pentra utilizes X-ray technology for liquid level inspection and employs sensors to detect uncovered products. An optional independent can wall inspection module is available specifically for slim cans.

For code inspection or additional inspection functions, please select alternative modular full-can inspection systems.

Adopts XispVision® universal inspection software platform

Adopts XispVision® universal inspection software platform

All-in-one design for easy installation and integration

All-in-one design for easy installation and integration

Reliable and cost effective

Reliable and cost effective

Suitable for aluminum and tin cans

Suitable for aluminum and tin cans

Low fill level

Low fill level No cap

No cap

|

|

| Low fill level | No cap |

Minimal safe radiation exposure level

Minimal safe radiation exposure level

Low-energy eco-friendly X-ray tube

Low-energy eco-friendly X-ray tube

Equipped with unlock and emergency stop

buttons

Equipped with unlock and emergency stop

buttons

Suitable for aluminum and tin cans

Suitable for aluminum and tin cans