XispVAS is installed inside the labeling machine, and through the principle of machine vision using two-stage positioning can realize the container surface marking, engraving, text, trademarks and other inspection features for positioning.

|

Scope of application:

|

Installation Position:

|

XispVAS Positioning System is designed to inspect containers of various materials and sizes, including glass beer bottles, purified water PET bottles, large oil drums, and other container types. For diverse container specifications and inspection features, Xispek offers customized solutions to meet specific requirements.

With the increasing diversification of end-product packaging formats and growing demand for high-precision labeling, the system addresses challenges across industries—from premium printed containers in beer/beverage sectors to specialized bottle shapes in condiments and chemical industries. Label positioning accuracy directly impacts visual consistency and brand integrity. The XispVAS system employs machine vision technology to precisely align containers by controlling servo motor rotation within labeling machines, ensuring uniform label placement and aesthetic standardization.

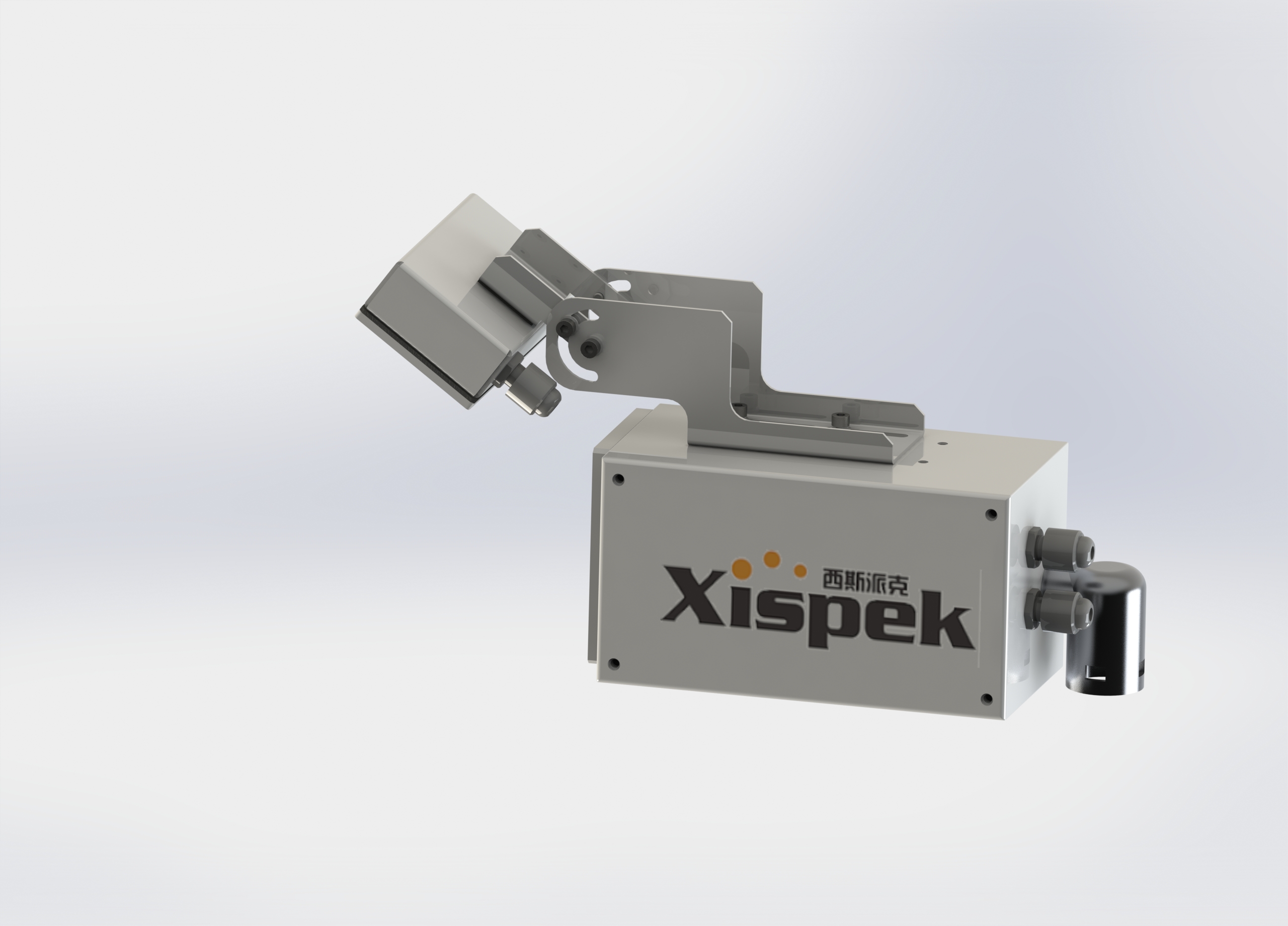

The Xispek XispVAS positioning system

employs a two-stage alignment process: precision positioning and reservation

positioning . Different control centers can be selected according to production

line speed requirements. The system achieves high-speed labeling positioning up

to 72,000 bottles per hour.

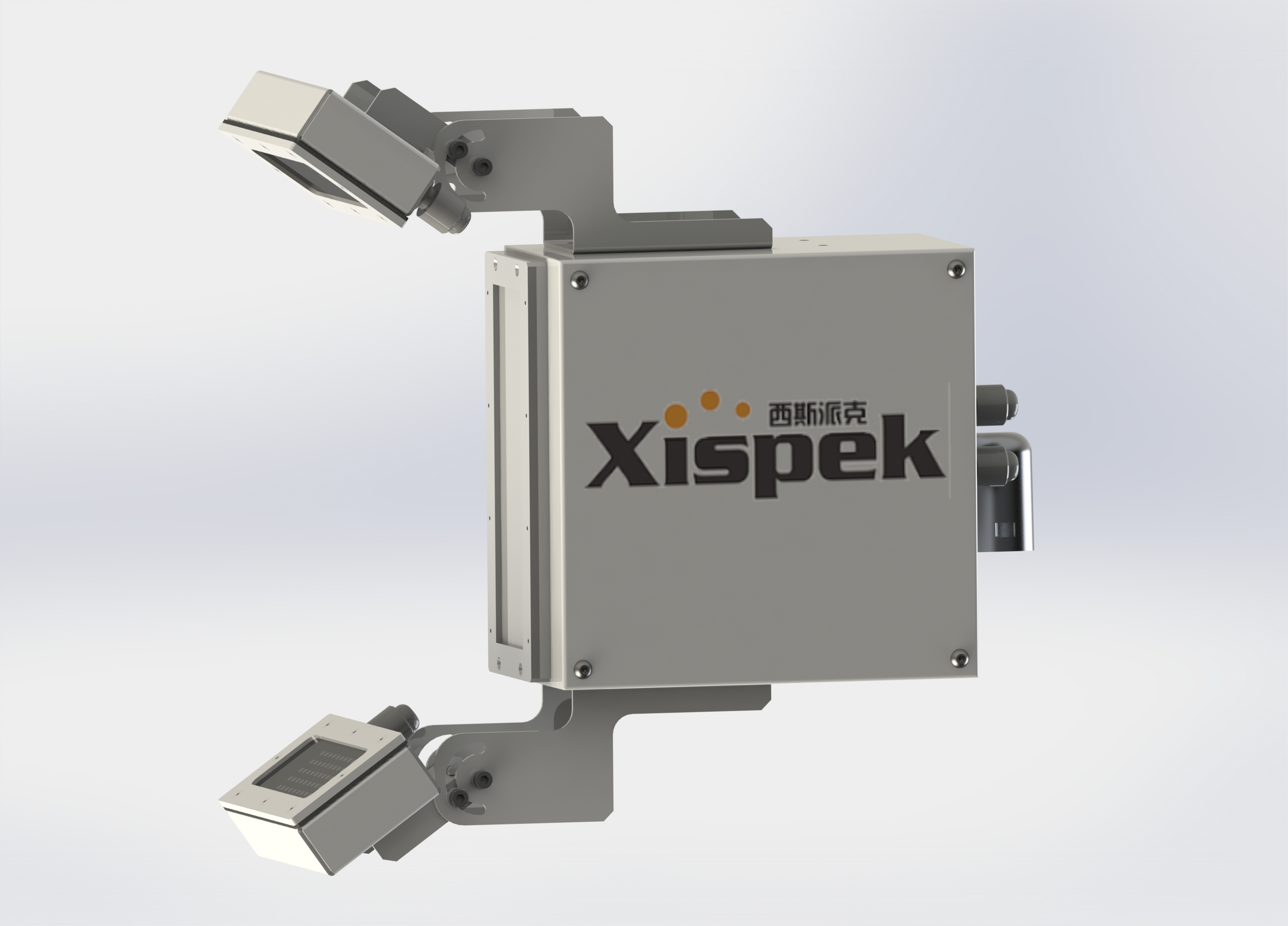

Precision positioning:

Precision positioning:

The Precision positioning module uses three high-speed industrial cameras. The container rotates in the process of Precision positioning, and the pre-positioning module shoots the surface of the container several times during the process of container rotation to construct all-round information data of the container. Through the intelligent image processing algorithm to determine the actual position of the container, and finally control the servo motor rotation in the labeling machine to complete the first level of positioning function.

Reservation positioning:

Reservation positioning:

The Reservation System again takes a picture of the container surface and makes a correction to the position of the container to ensure millimeter-level accuracy in positioning.

Powerlink

Powerlink

TCP/IP

TCP/IP

Modbus/TCP

Modbus/TCP

Ethernet/IP

Ethernet/IP

ProfiNet

ProfiNet

CAN

CAN

Adopts XispVisionpositioning accuracy can reach up to ±0.1mm at most

Adopts XispVisionpositioning accuracy can reach up to ±0.1mm at most

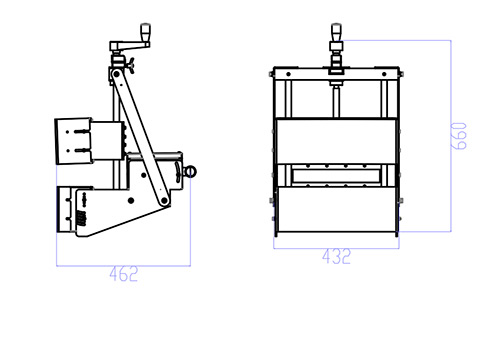

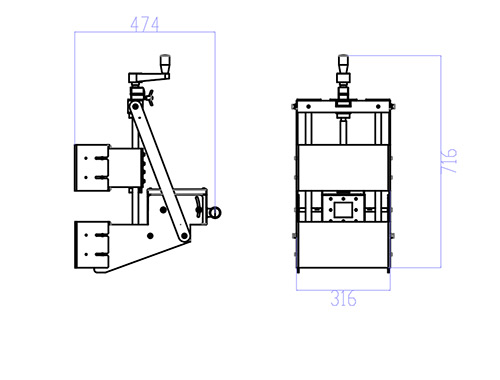

Compact and easy to integrate into the labeling machine

Compact and easy to integrate into the labeling machine

Non-contact positioning, no abrasion

Non-contact positioning, no abrasion

Simple changeover, no need to replace product parts

Simple changeover, no need to replace product parts

Hygienic design for various environment

Hygienic design for various environment