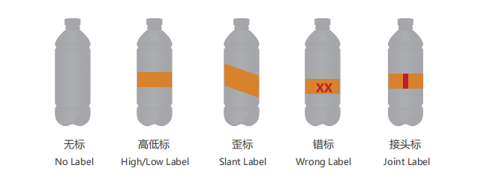

Etika360 label inspection system uses advanced visual recognition technology to inspect labels in a 360-degree view, capturing defects on every angle, including no label, wrong label, high/low label, slant label, and joint label.

|

Scope of Application:

|

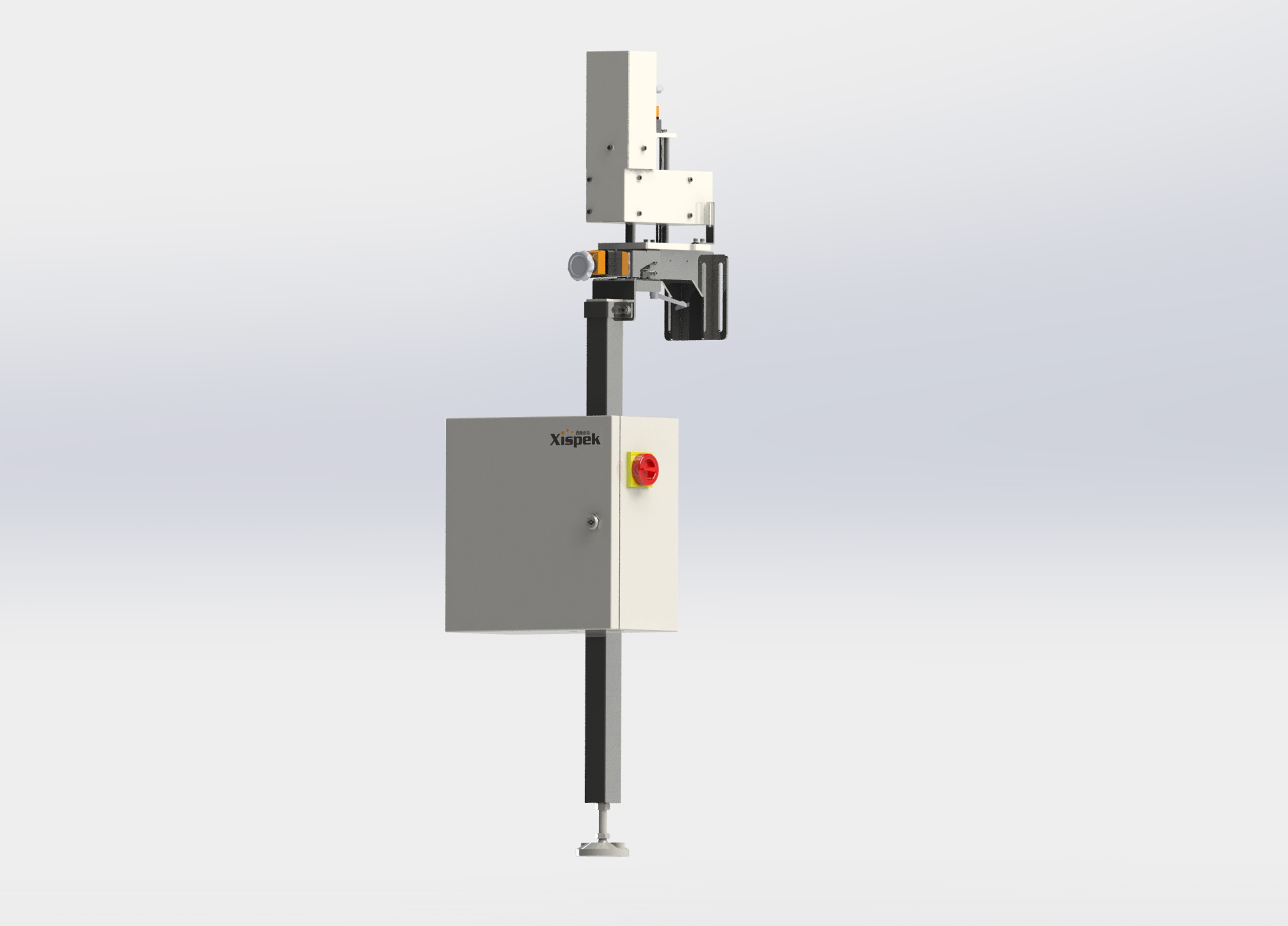

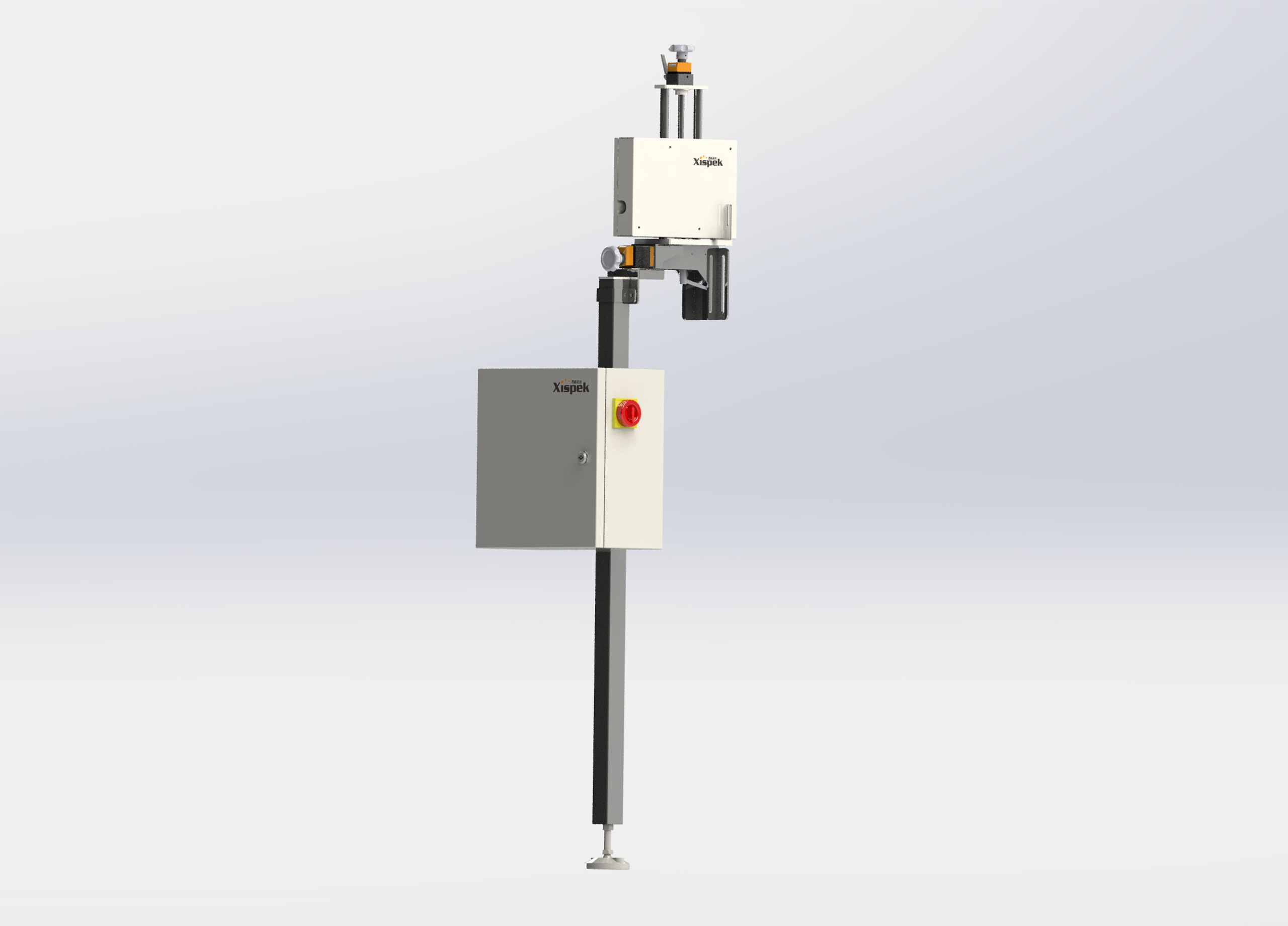

Installation position:

|

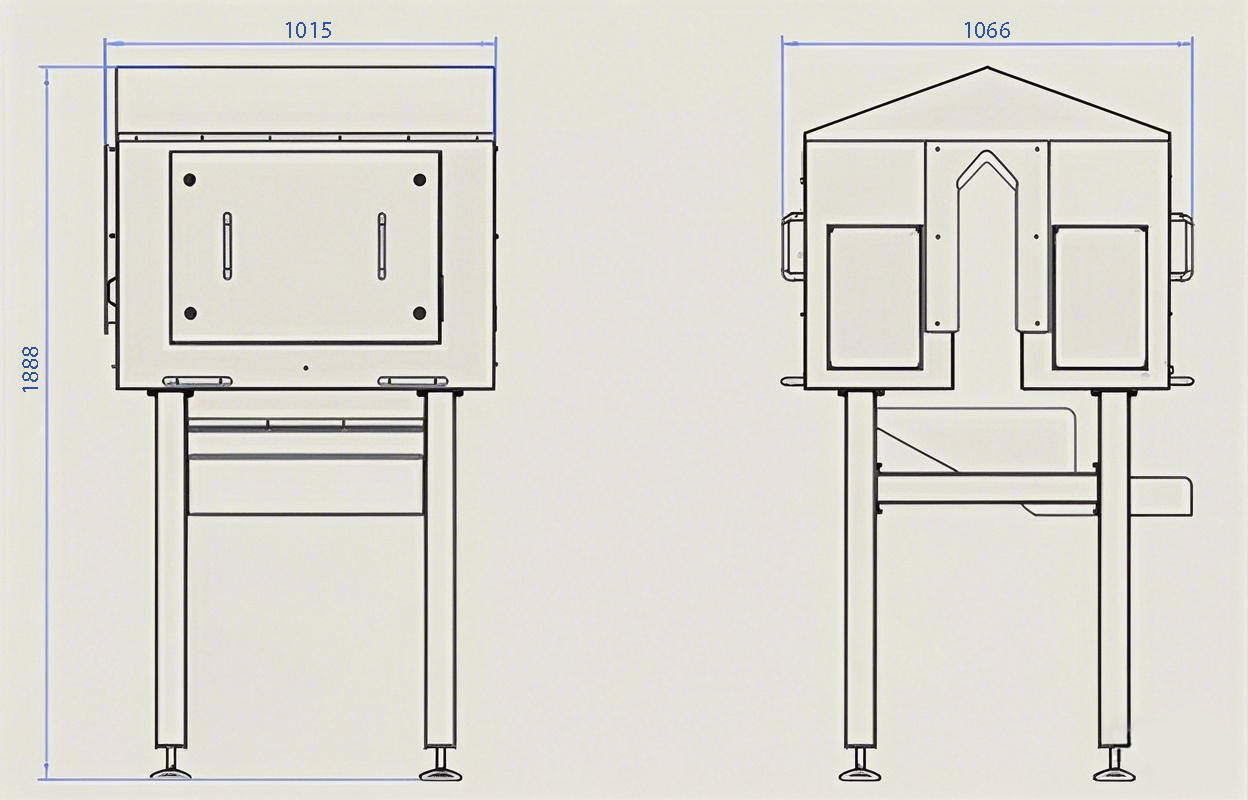

The Etika360 label inspection system has overall dimensions of 1015*1066*1888mm (LWH) and achieves an inspection speed of 60,000 bottles per hour.

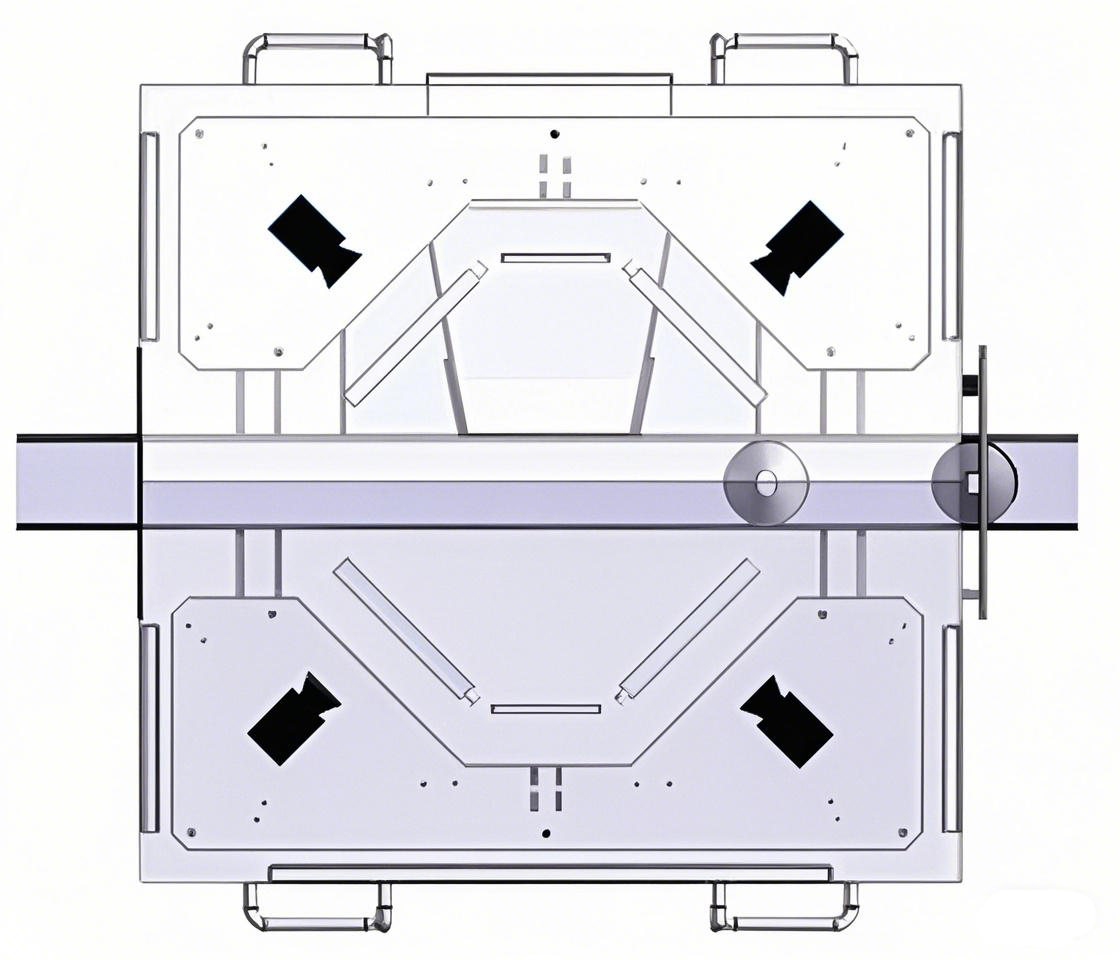

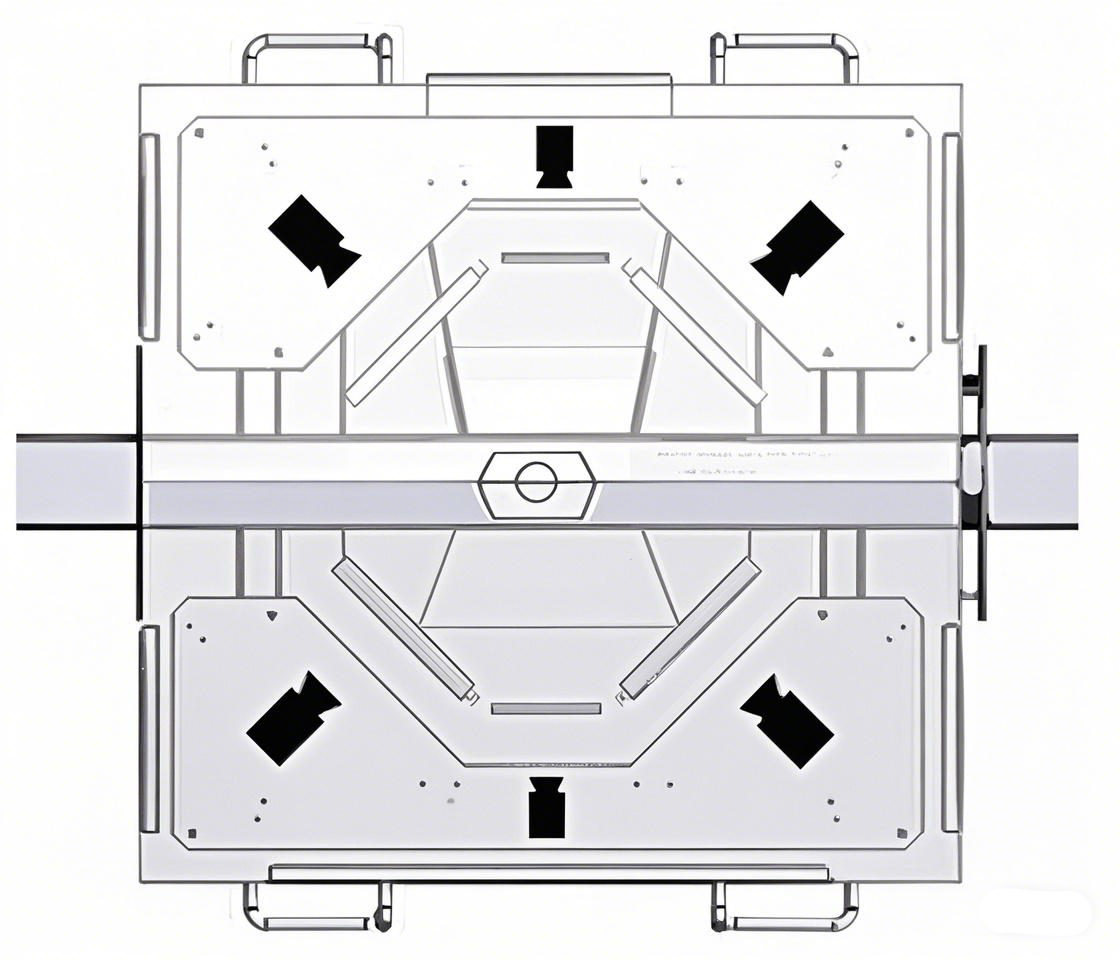

The Etika360 label inspection machine is installed on the conveyor belt after the labeling machine. It utilizes four color industrial cameras to capture 360-degree imaging of container labels, effectively resolving position offset and rotation angle issues caused by container movement on the conveyor. Through high-efficiency image processing algorithms, it reconstructs complete label images and performs highly effective label defect inspection. Additionally, an optional 6-camera configuration compatible with square bottle label inspection is available, addressing the significant label distortion that often occurs due to shooting angles on square bottles.

No label

No label

High/Low Label

High/Low Label

Slant label

Slant label

Wrong label

Wrong label

Joint label

Joint label

Inspection module with IP65 protection level

Inspection module with IP65 protection level

Utilizes an in-machine thermostatic design

Utilizes an in-machine thermostatic design

Compatible with round and square bottles (Etika360-G6)

Compatible with round and square bottles (Etika360-G6)