Base Inspection Module is installed within the blow molder of PET production lines to inspect:

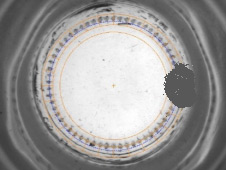

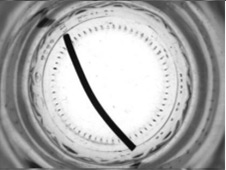

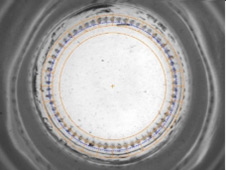

Base cracks, Base contamination, Eccentric gate points

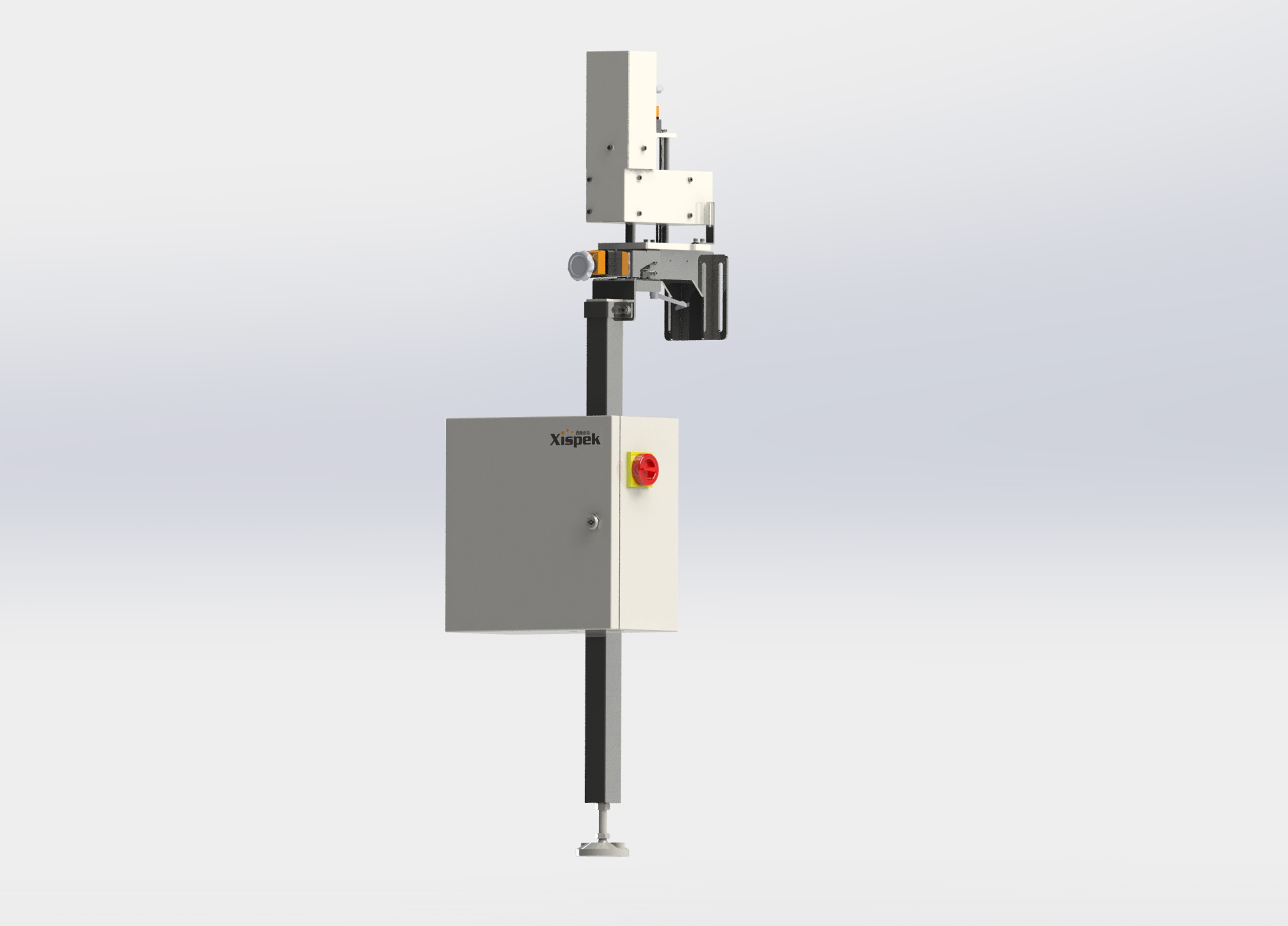

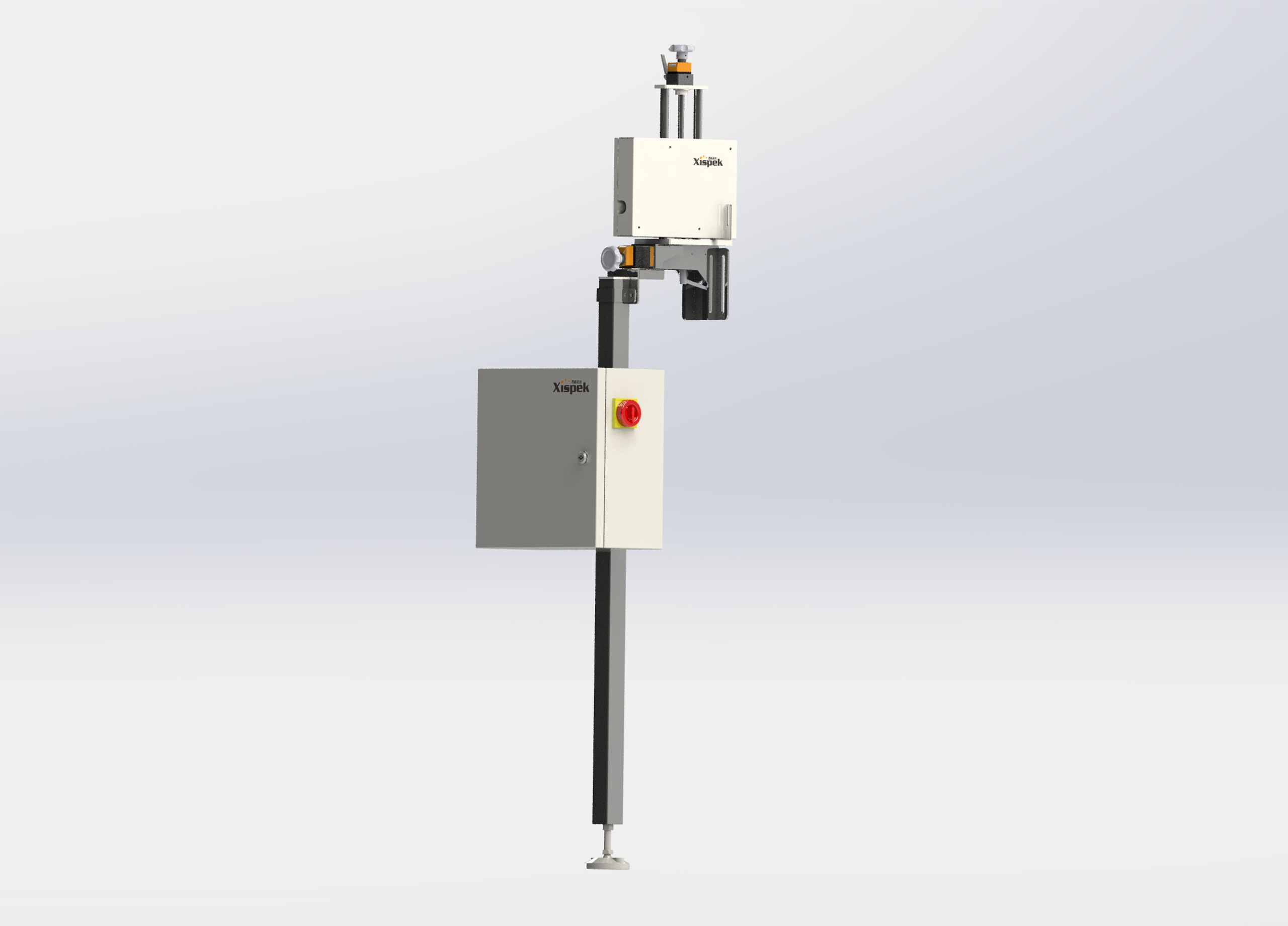

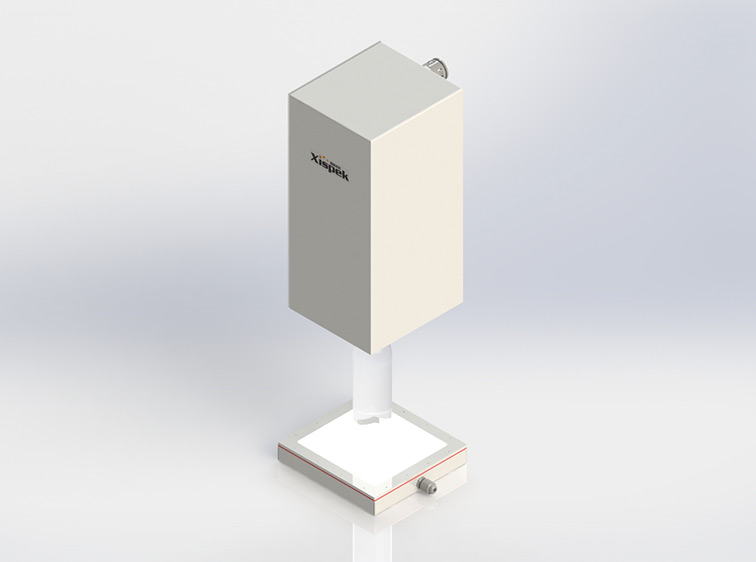

Utilizes high-performance industrial cameras and maintenance-free LED lighting to capture images of various preform openings, featuring a compact and flexible overall design.

|

Scope of application:

|

Installation Location:

|

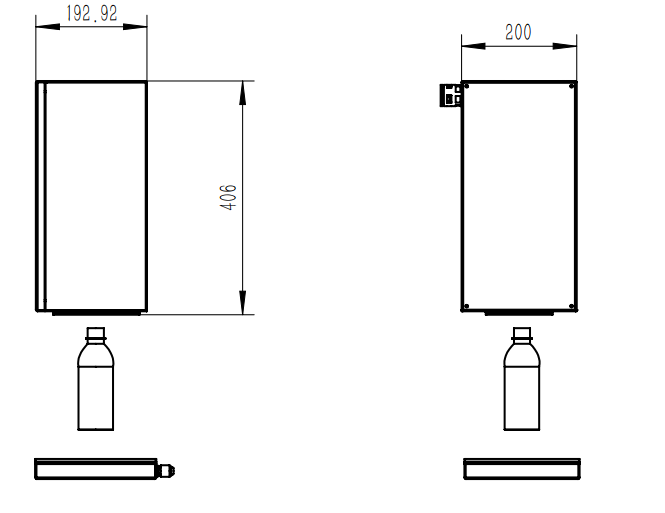

Base Inspection Equipment Dimensions: 192.92*200*406mm (LWH). It supports a maximum inspection speed of 72,000 bottles/hour.

Base Inspection Module employs a compact modular design for installation in various blow molding machines. Typically integrated post-blow molding and pre-filling on PET production lines, it conducts individual bottle base inspection. When line configuration permits, additional neck and body inspection modules can be incorporated for comprehensive empty bottle inspection, significantly improving filler-bound container qualification rates.

Breakage

Breakage

Contamination

Contamination

Eccentricity

Eccentricity

|

|

|

|

Breakage |

Contamination |

Eccentricity |