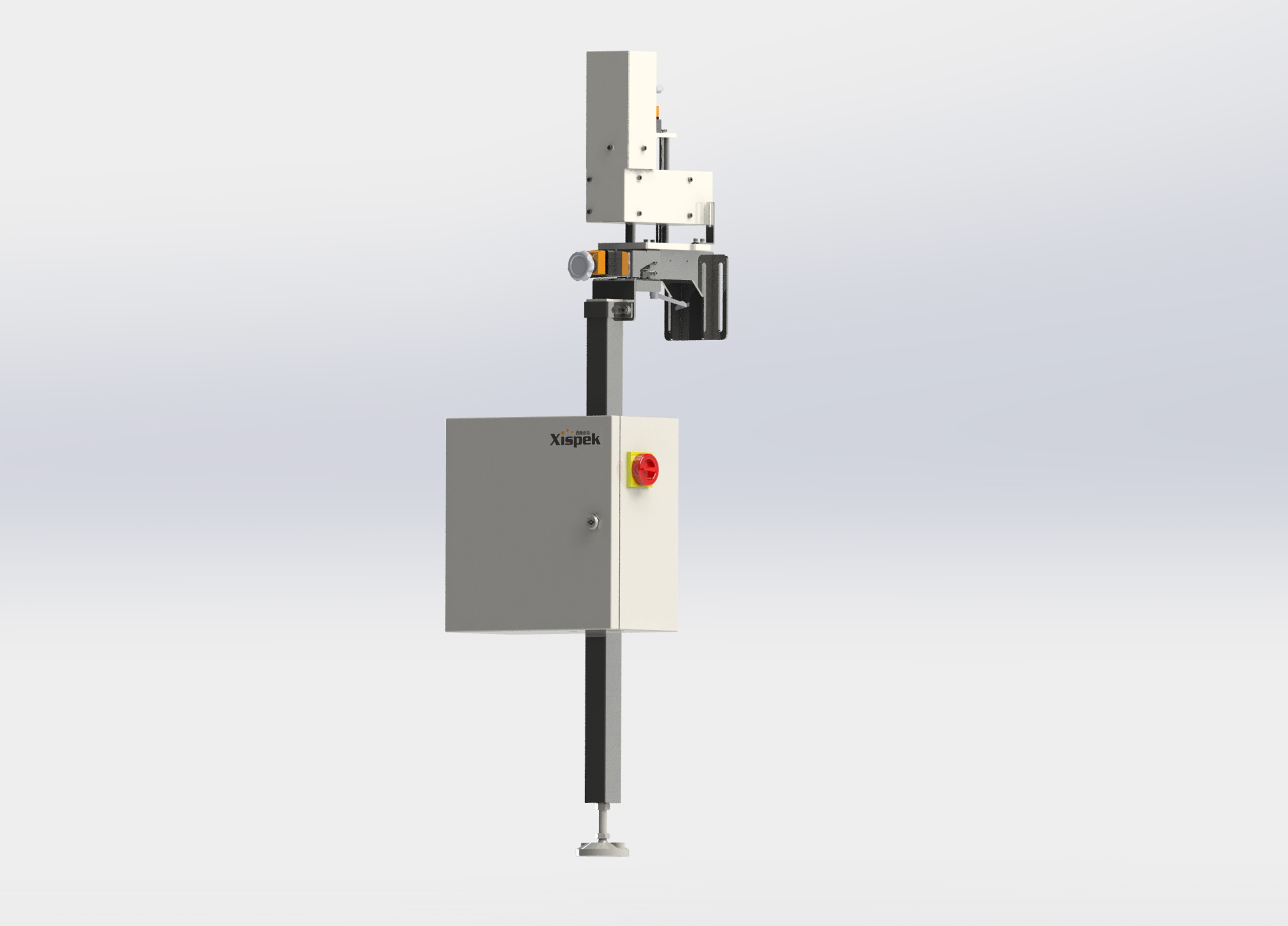

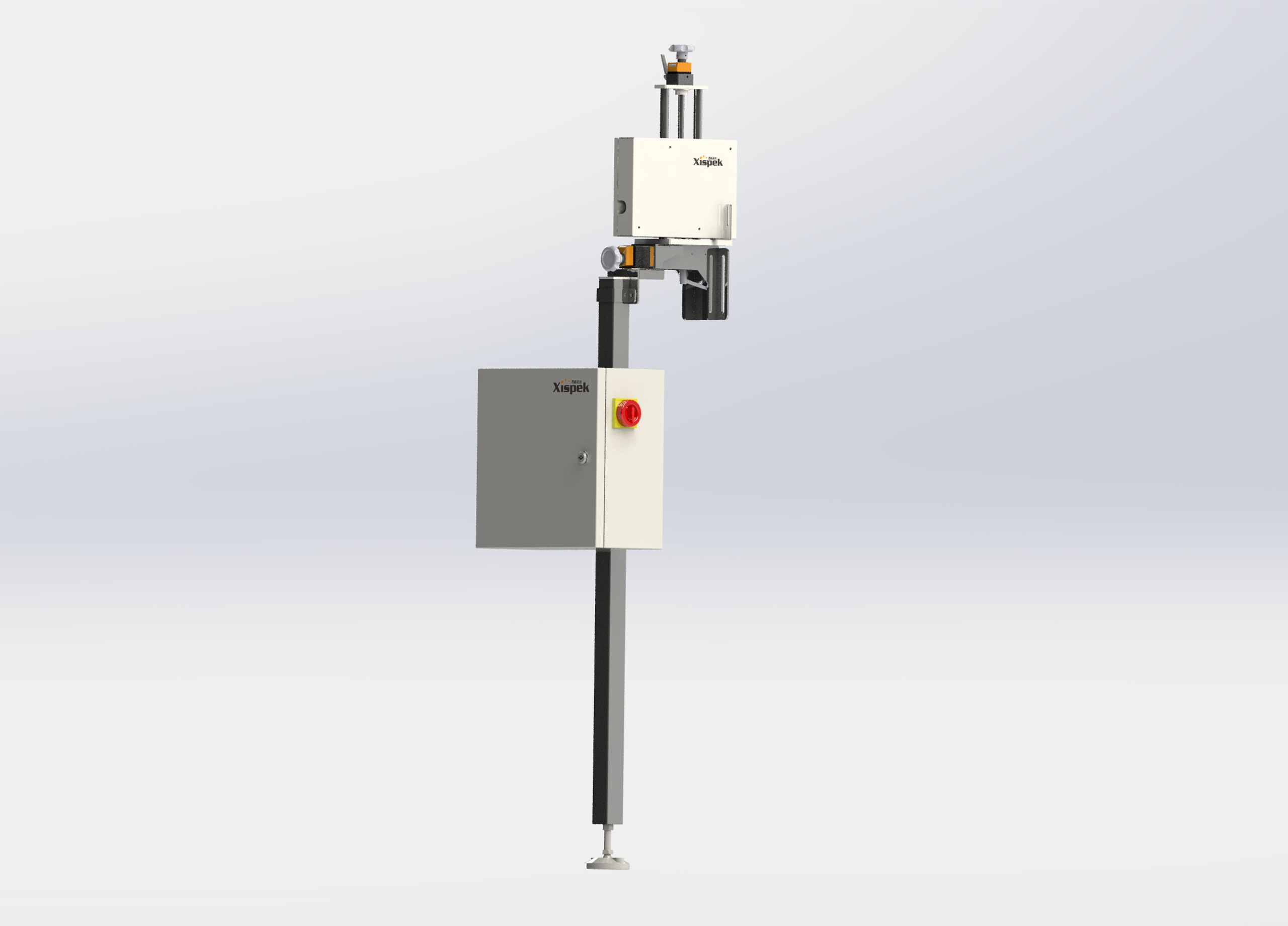

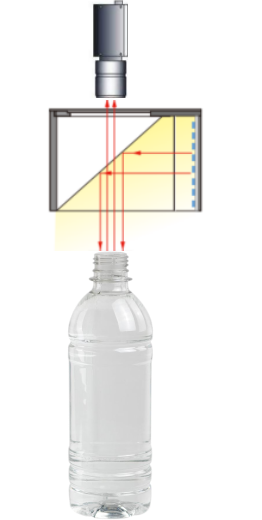

Preform Finish Inspection Module BFI is installed inside the PET production line of the blowing machine, inspection items include preform finish gap, size, and roundness. It adopts high quality industrial camera and maintenance-free LED light source to photograph various types of nicks, and the overall design is compact and flexible.

|

Scope of application:

|

Installation position:

|

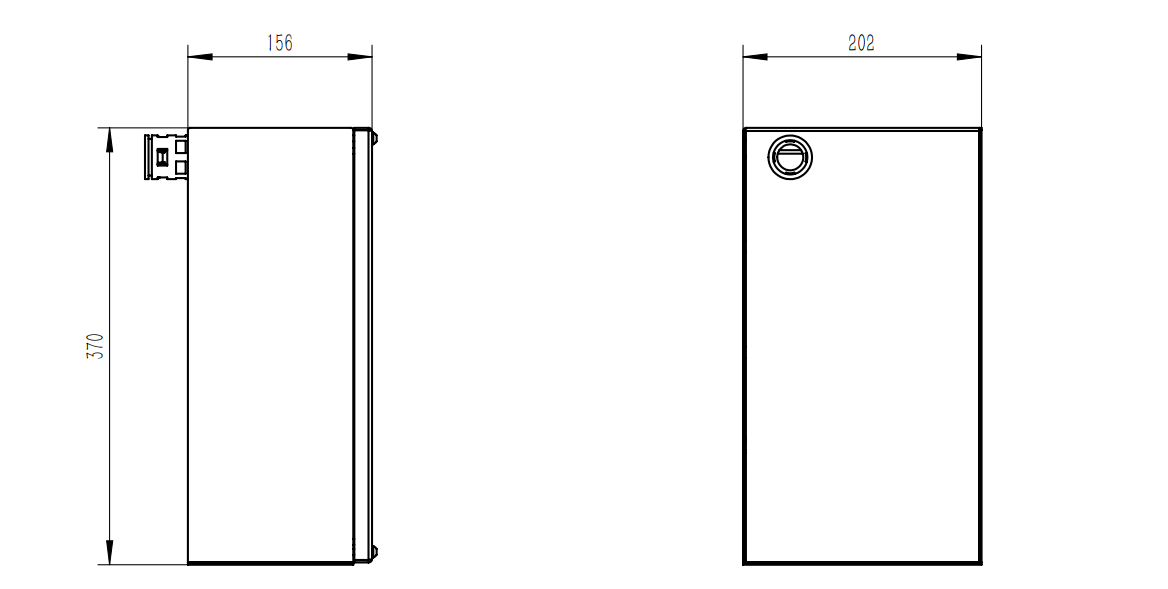

Bottle finish inspection equipment dimensions: 202*156*370mm (LWH). It supports a maximum inspection speed of 72,000 bottles/hour.

The bottle finish inspection module features a compact modular design, enabling installation in blow molders of various sizes. It is typically installed after the blow molding process and before the filling machine on PET production lines, conducting individual finish inspections. When production line space permits, additional body and base inspection modules can be integrated to perform comprehensive empty bottle inspection, effectively improving the qualification rate of empty bottles entering the filling machine.

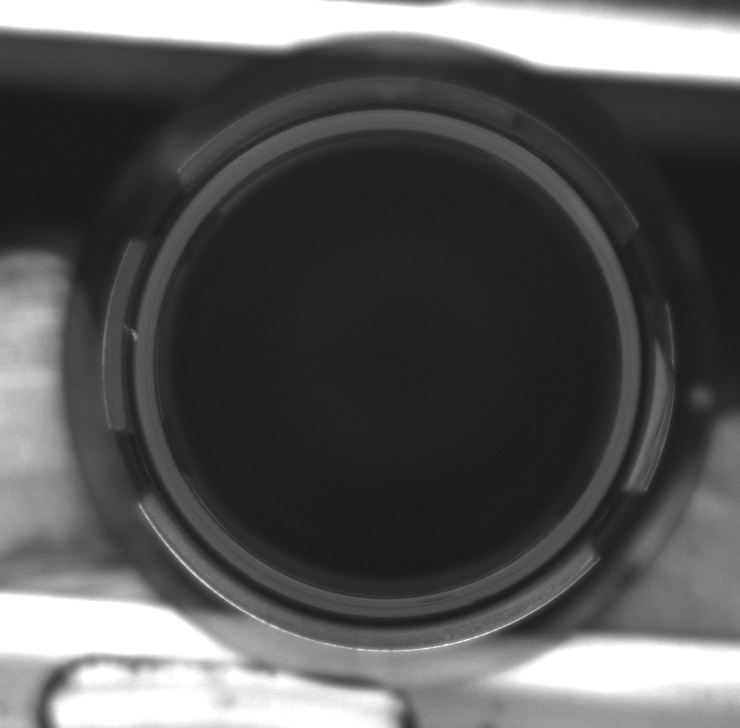

Gap

Gap

Roundness

Roundness

Size

Size

|

|

|

|

|

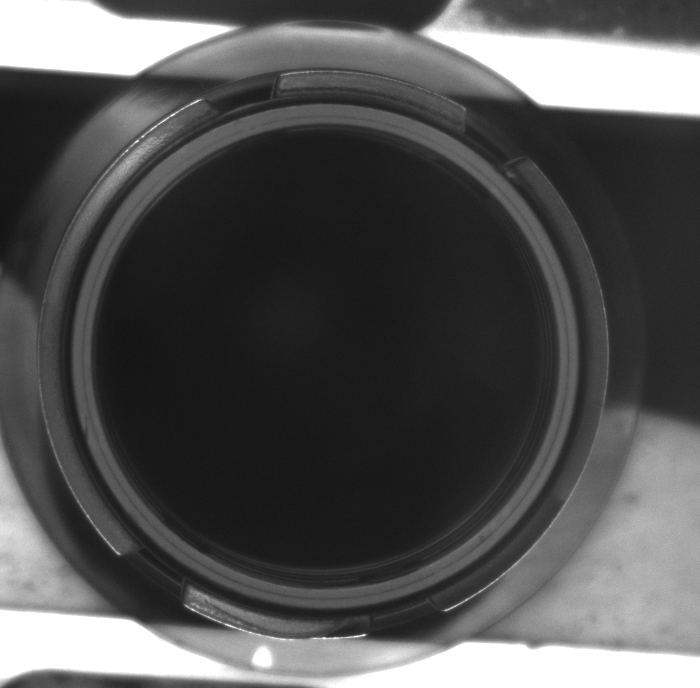

Normal finish |

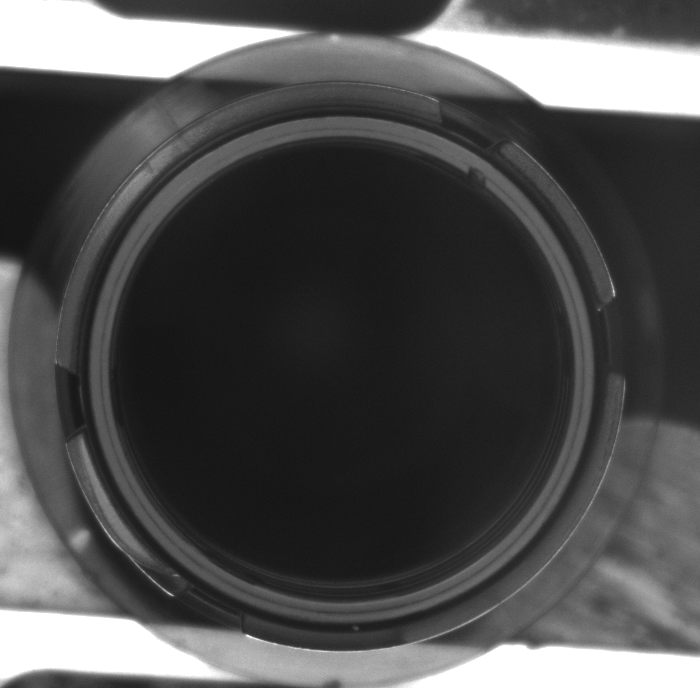

Gap | Roundness |

|

|

Size |

|

|

|

Adpots XispVision® universal inspection software platform

Adpots XispVision® universal inspection software platform

High inspection efficiency and inspection accuracy

High inspection efficiency and inspection accuracy

Compact design for easy integration

Compact design for easy integration

Inspection module with IP65 protection level

Inspection module with IP65 protection level

Can be flexibly combined with other functional modules according to customer needs to form a multi-functional inspection device that meets customer requirements

Can be flexibly combined with other functional modules according to customer needs to form a multi-functional inspection device that meets customer requirements