The Promita-P One is an integrated full-bottle inspector designed, performing online inspection of filled PET bottles post-filling. It ensures product quality by reliably inspecting fill levels, caps, spray codes, and other critical modules, followed by automatic rejection of defective products.

As an essential component of the bottling process, the Promita-P One enhances production efficiency, precision, and control, delivering safer and higher-quality products to consumers. Additionally, it can be integrated with a filling management system to trace defective products on the production line, enable real-time monitoring, and minimize production losses.

|

Scope of application:

|

Installation position:

|

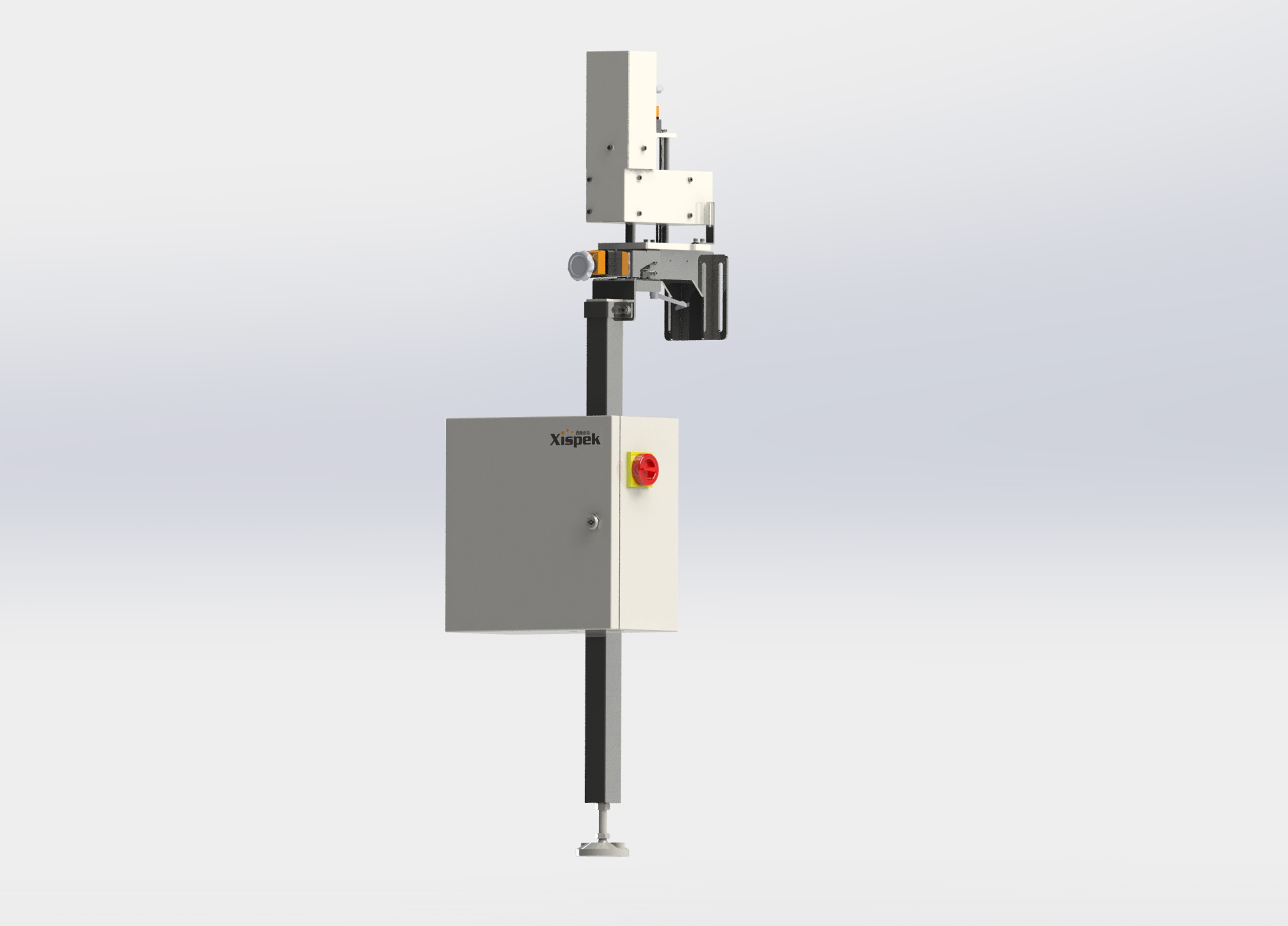

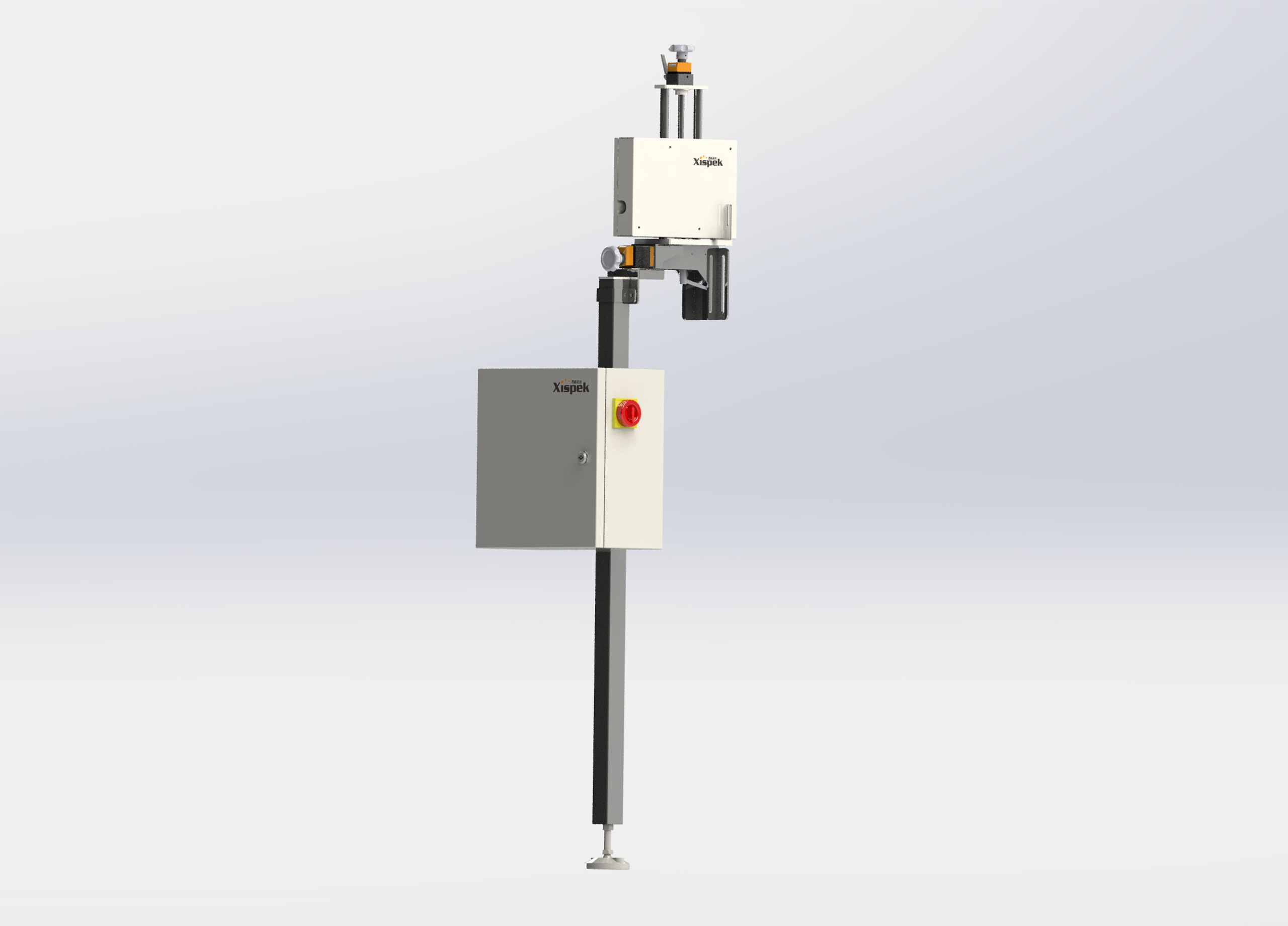

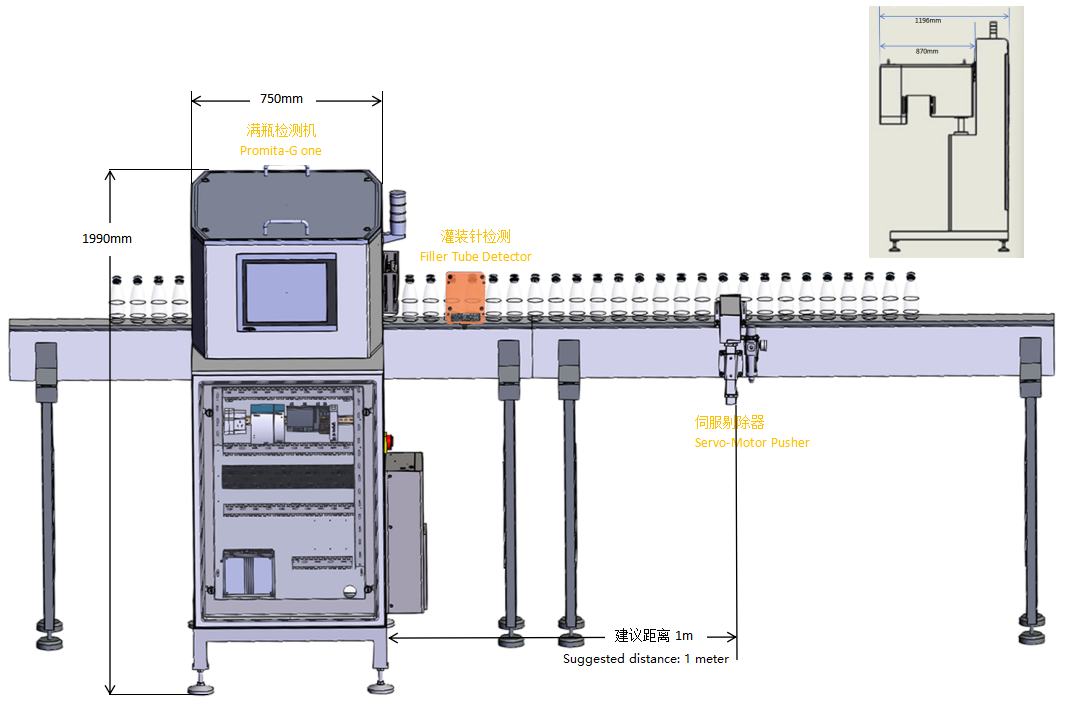

The Promita-P One is an integrated inspection system combining liquid level, cap, and coding presence for full bottles. It utilizes a combination of imaging and sensor technologies to ensure precise inspection for each container. Equipment dimension: 750mm× 1196mm× 1990mm (length*width*height), with a maximum inspection speed of 72,000 bottles/hour.

The Promita-G One full bottle inspection machine adopts fully automatic height adjustment (height adjustment range: 250mm) with one-touch product changeover, adapting to different product formulas and selecting corresponding control centers according to different production line speeds.

The fill level inspection (FLI-G) module utilizes high-resolution cameras and specially designed light-reflecting panels to distinguish between high, low, and normal fill levels, avoiding false judgments caused by foam. The cap inspection (SCI-3) module inspects crown cap conditions including missing caps, high caps, low caps, skewed caps, and deformed caps. The coding inspection module identifies the presence or absence of codes on bottle bodies or caps, and can be expanded to inspect partial code missing and perform OCR code recognition. The cap top logo inspection inspects the presence or absence of logos on cap tops.

Additionally, optional modules include a filling management system and metal filling needle inspection, enabling traceability of inspection products on the production line, real-time monitoring of production operations, rejection of products containing metal, reducing production losses, and improving production line efficiency.

Fill Level Inspecion

Fill Level Inspecion Cap Inspection

Cap Inspection Code Presence

Code Presence Top Logo Inspection(Optional)

Top Logo Inspection(Optional) Metal filling needle inspection(Optional)

Metal filling needle inspection(Optional) Filler Management System(Optional)

Filler Management System(Optional)

Inspects the liquid level inside bottles.

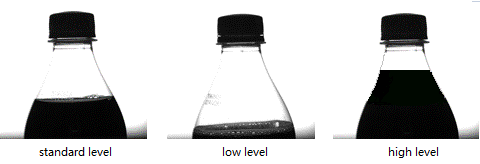

The liquid level inspection employs an industrial camera paired with a maintenance-free, long-life infrared LED light source. The strong penetration capability of infrared light enhances imaging contrast, effectively eliminating interference from foam inside bottles during level inspection.

Additionally, the XispVision inspection platform precisely calculates liquid level height by comparing left-right level differences. This compensates for liquid surface tilt effects during high-speed bottle movement, achieving ±1mm inspection accuracy to ensure system efficiency and stability.

Optional X-ray level inspection:This configuration provides the advantage of inspecting levels in products where cameras cannot capture the liquid surface (e.g., aluminum cans).

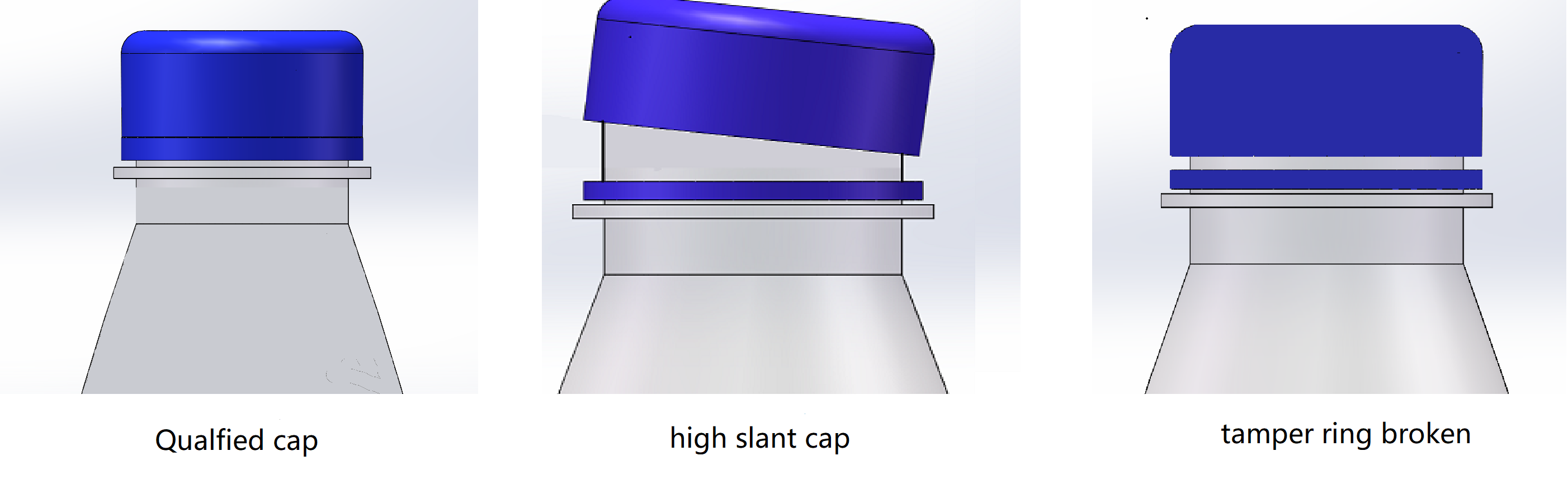

Inspects crown cap conditions including missing caps, high caps, low caps, skewed caps, and deformed caps.

The cap inspection system adopts three industrial cameras and a maintenance-free, long-life white LED light source design, utilizing backlight imaging to enhance contrast. With a precision optical reflection system, it achieves 360° inspection of the cap's profile, enabling the rejection of high/skewed caps, missing caps, and deformed caps. The inspection accuracy for high/skewed caps is ±1mm.

For basic cap presence inspection only, an optional crown cap inspection sensor is available.

Primary Function: Inspection of Code Presence

The code inspection system is designed to verify the presence of printed or laser codes, ensuring proper marking on products.

Inspects the presence/absence of top logo and incorrect pattern colors on mismatched caps.

Uses one color industrial camera and ring LED light source to inspect mismatched caps through color and pattern verification. Additionally, cap roundness measurement can determine whether the cap is crushed, adding an extra safety check to cap inspection. Expandable QR code/barcode content recognition capability.Inspects the resence of metal filling needles and other metal contaminants in bottle bottoms.

Implemented using high-sensitivity metal inspectors installed on both sides of the conveyor belt. Integrated with flexible rejection systems to uniformly collect and process defective.

Integrate the inspection system with a real-time tracking system to correlate inspection statistical results with the positions of filling valves and capping heads within the filling machine. Each filling head or other traceable equipment is equipped with a photoelectric sensor, which triggers the creation of an independent channel to monitor the product until the channel is closed upon rejection, achieving traceability. When the system detects frequent underfilling from a specific filling valve or consistent misaligned caps from a capping head, it proactively alerts operators for targeted maintenance. This assists the factory in implementing preventive maintenance for faults, reducing downtime, and enhancing production stability.

Supports customizable sampling plans, allowing flexible setting of sampling rules (e.g., taking 10 samples from a specified filling valve or batch-sampling all stations). Simply input the requirements, and the system will automatically execute the process, ensuring efficient, accurate, and traceable sampling—significantly improving quality control efficiency.

The filling management system features the following:

TrackML® patented tracking technology

TrackML® patented tracking technology

Individual statistical summary for each

filling head (capping head)

Individual statistical summary for each

filling head (capping head)

Problem diagnosis through equipment

analysis

Problem diagnosis through equipment

analysis

Sampling functionality

Sampling functionality

Itemized statistics by machine position

Itemized statistics by machine position

Graphical and tabular reporting function

Graphical and tabular reporting function