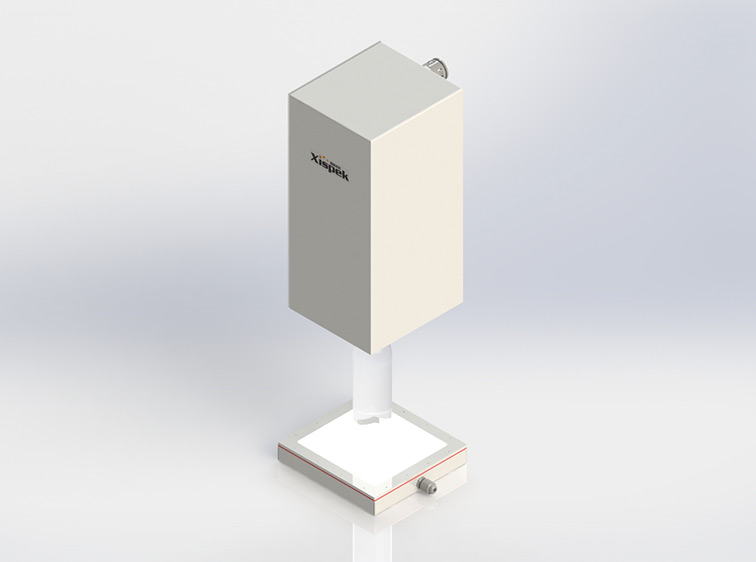

Empty Bottle Inspection Module is installed inside the PET production line's blow molding machine, inspecting for:Bottle mouth defects、Bottle mouth dimensions、Bottle mouth roundness、Bottle base defects、Bottle base contamination、Bottle base eccentricity.

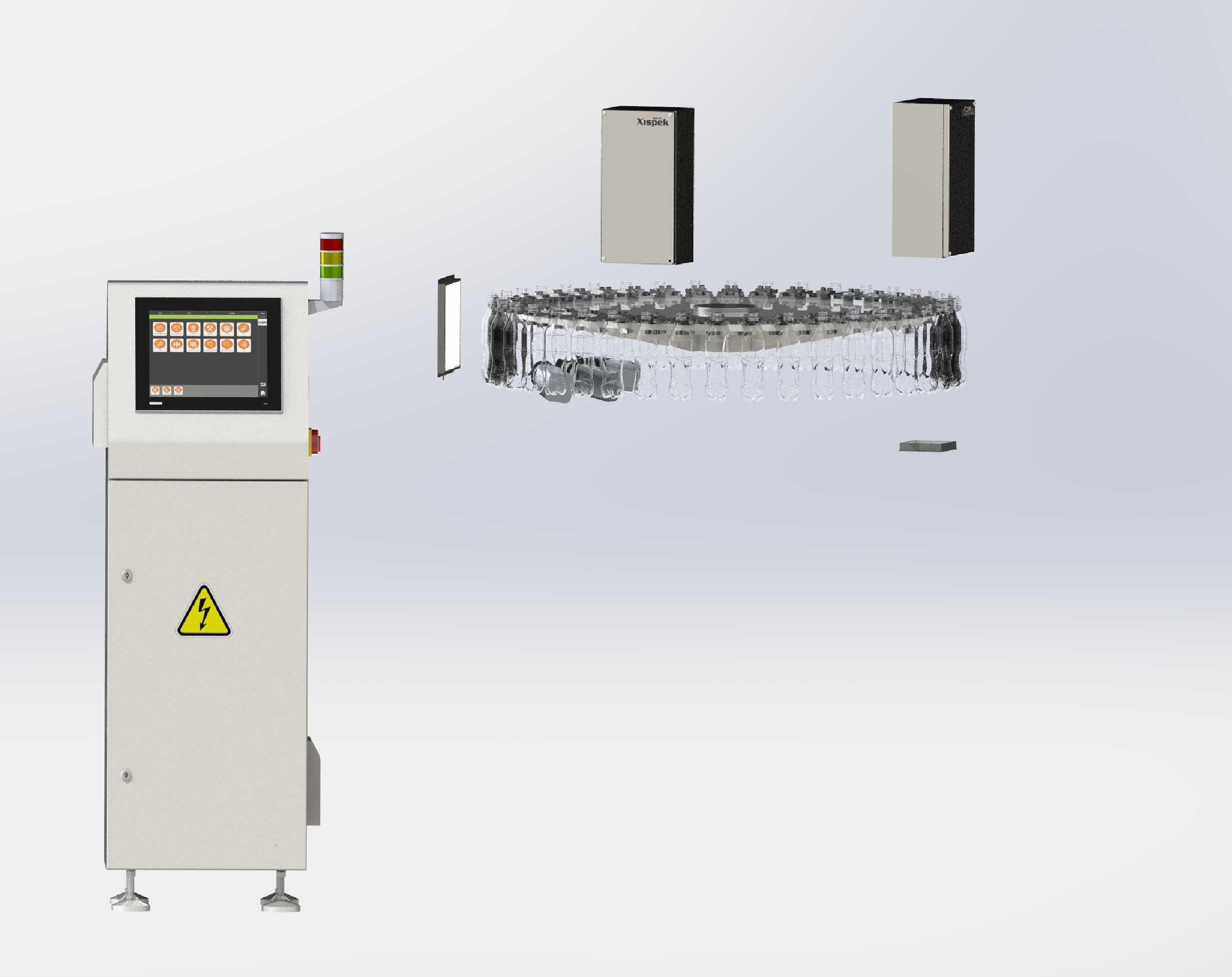

Installed after the blow molder on the transfer starwheel, the compact modular design enables empty bottle inspection to be integrated with blow molders of various sizes. The inspection system consists of bottle mouth and base inspection modules, performing quality checks on bottle mouths and bases post-blow molding. Different control centers can be selected based on production line speeds, achieving a maximum label inspection capacity of 72,000 bottles/hour.

Bottle mouth defects: Cracks, Scratches, Roundness deviation

Bottle mouth defects: Cracks, Scratches, Roundness deviation

Bottle body defects: Holes, Black spots, Air bubbles

Bottle body defects: Holes, Black spots, Air bubbles

Bottle base defects: Material loss/damage, Contamination, Eccentric blow-molding point

Bottle base defects: Material loss/damage, Contamination, Eccentric blow-molding point

Compact design for easy integration into blow molding machines

Compact design for easy integration into blow molding machines

Inspection module features IP65 protection rating, suitable for harsh environments

Inspection module features IP65 protection rating, suitable for harsh environments

Flexible configuration allows combination with other functional modules (e.g., preform inspection) to meet diverse inspection requirements based on customer needs

Flexible configuration allows combination with other functional modules (e.g., preform inspection) to meet diverse inspection requirements based on customer needs