Empty can inspection system Nulla typically use machine vision technology, combined with high-speed cameras and image processing algorithms, to perform a full range of quality inspections on empty cans, including appearance defects, dents, scratches, deformations, and other issues. It also ensures the sealing performance of the can finish by detecting any damage or deformation to avoid leakage during the filling process.

|

Scope of Application:

|

Installation Location:

|

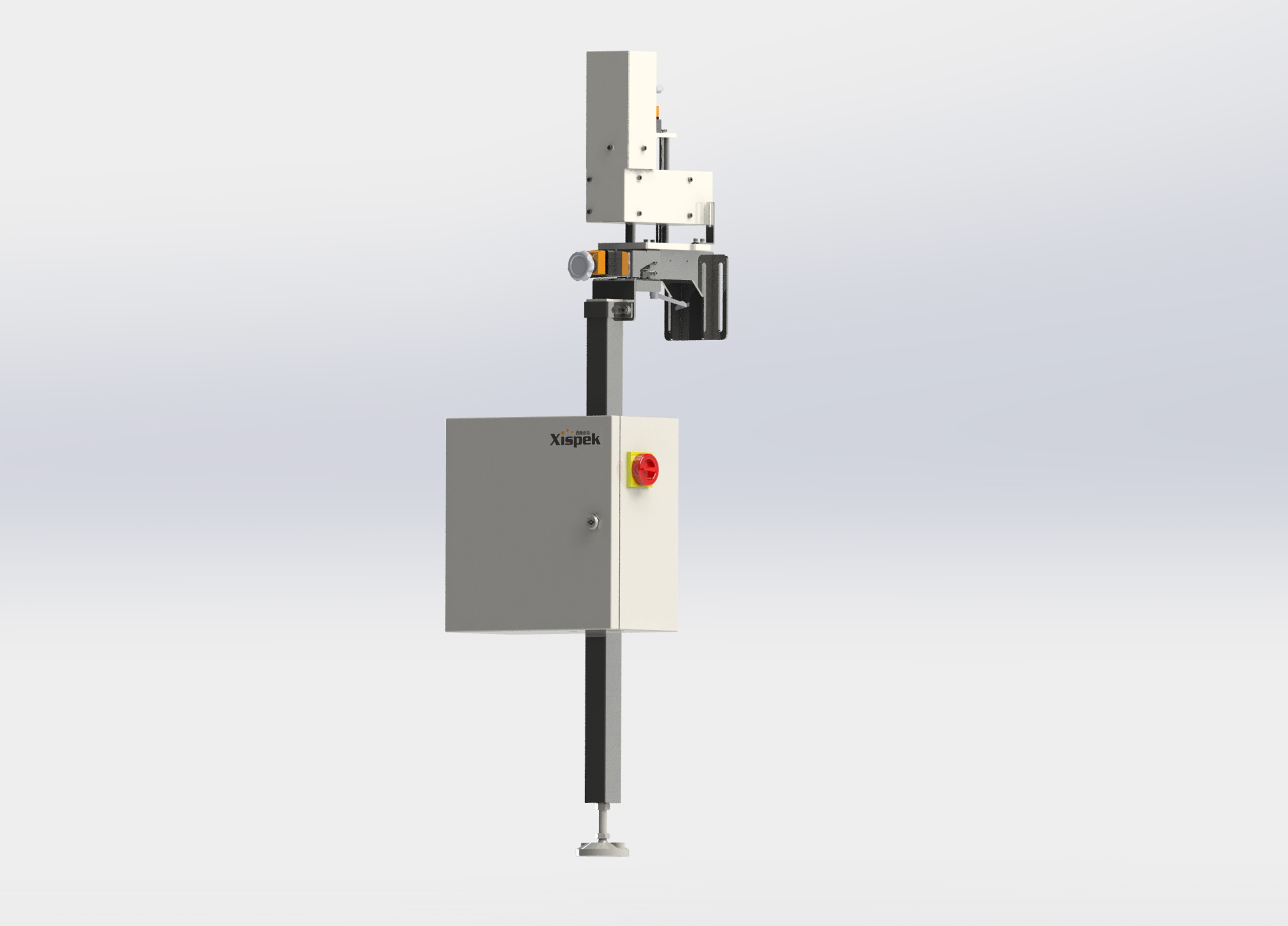

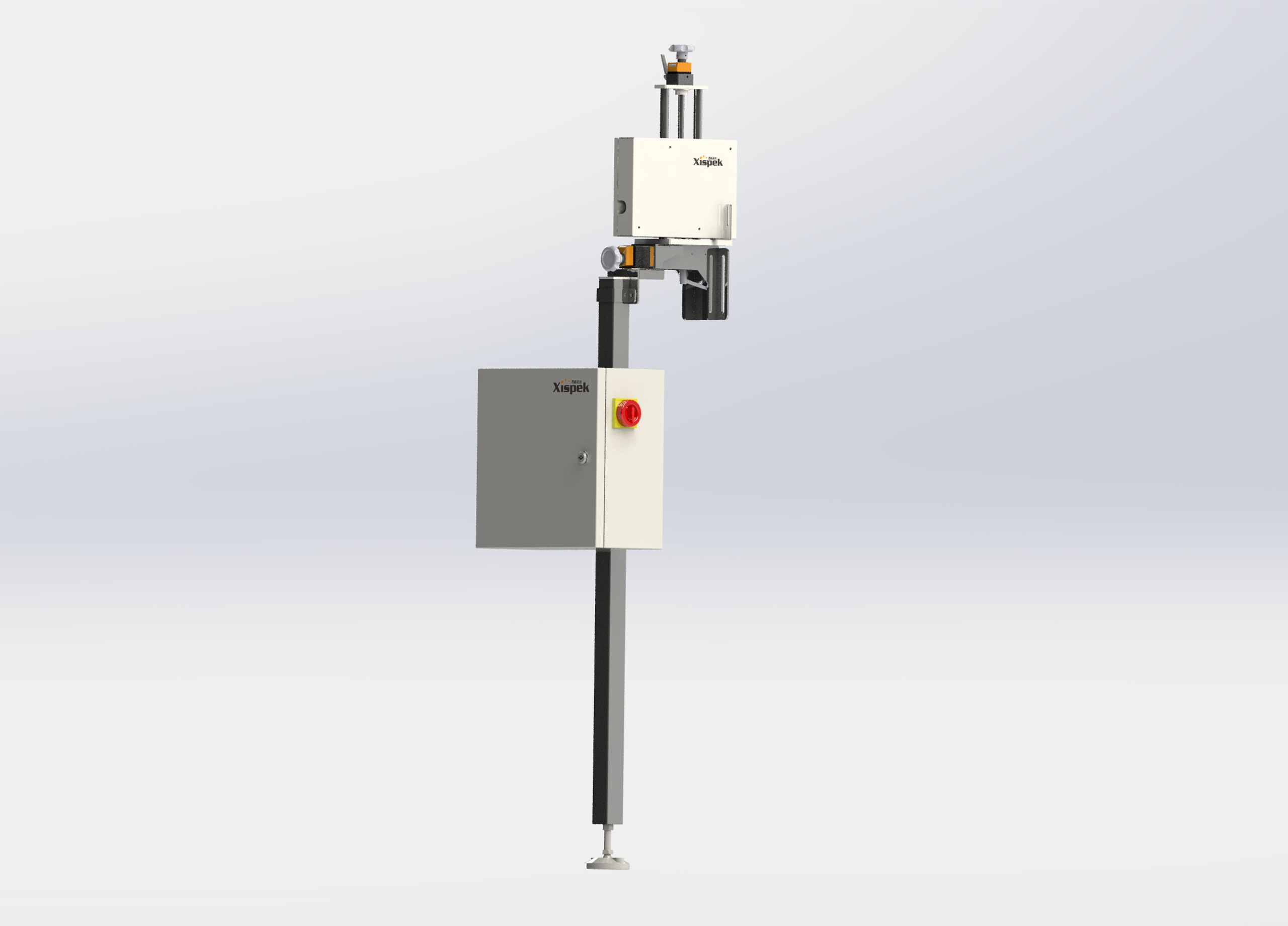

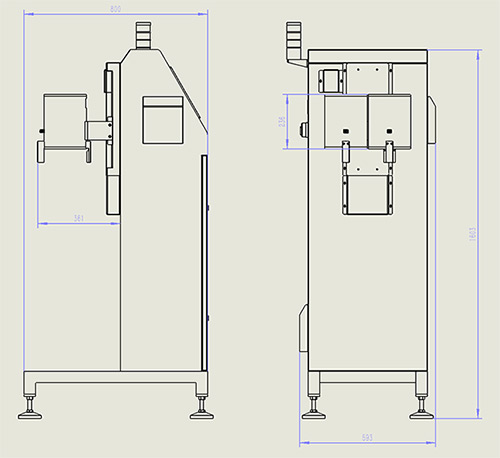

Empty Can Inspector ECI is a reliable and stable inspection equipment with dimensions of 800*593*1605mm (LWH). It supports optional control centers and achieves a maximum inspection speed of 120,000 cans/hour.

The ECI is installed on a single lane before the filling process. For high-speed production lines, this lane should be equipped with a vacuum adsorption system to securely hold empty cans on the conveyor belt, preventing slippage. The system uses high-speed cameras to precisely capture each can, inspecting for quality defects such as cracks, deformations, stains, etc., and enables fast and accurate rejection on high-speed production lines.

The ECI features height adjustment mechanisms with digital display and offers optional motorized adjustment for compatibility with various can types.

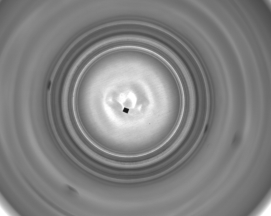

Can finish inspection

Can finish inspection

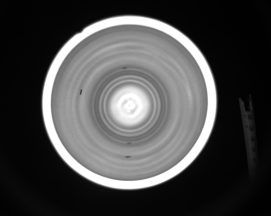

Can inner wall inspection

Can inner wall inspection

Can bottom inspection

Can bottom inspection

Dirty/ foreign matter at can neck, etc

Dirty/ foreign matter at can neck, etc

|

|

|

Can finish inspection |

Tank bottom inspection |

Inspection module with IP65 protection level

Inspection module with IP65 protection level

Equipped with vacuum adsorption system for high-speed production lines to ensure high-quality inspection

Equipped with vacuum adsorption system for high-speed production lines to ensure high-quality inspection

Manual and automatic adjustment mechanism optional

Manual and automatic adjustment mechanism optional

Compatible with all types of cans

Compatible with all types of cans