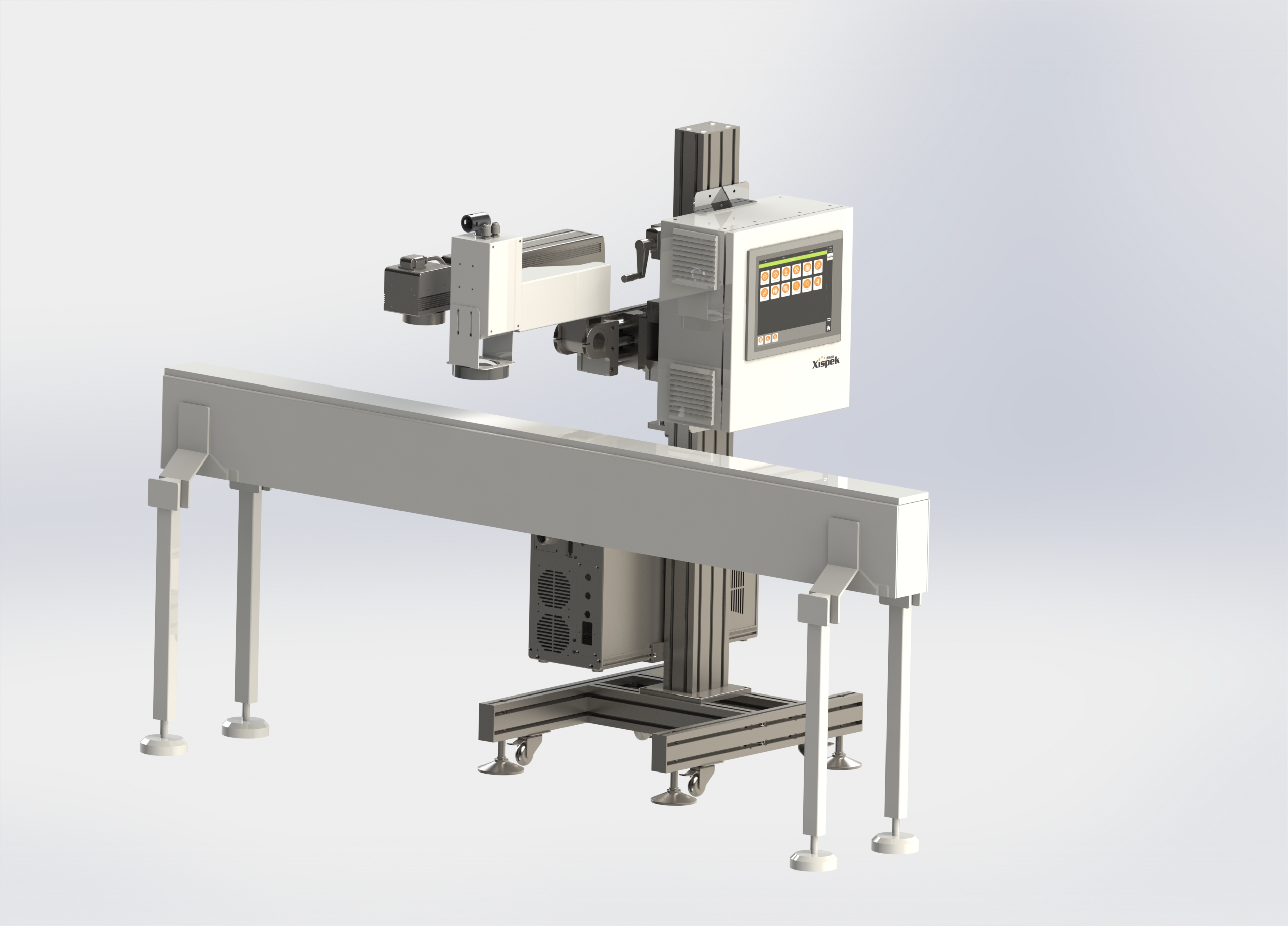

Can Code Inspection (VisCodia) is a system installed in the can production line to inspect the can code. It is a system that detects all kinds of poor codes, and adopts high-speed industrial cameras and the independent and autonomous XispVision® Universal Inspection Software Platform to accurately and efficiently identify the codes and reject the defective products.

|

Scope of application:

|

Installation position:

|

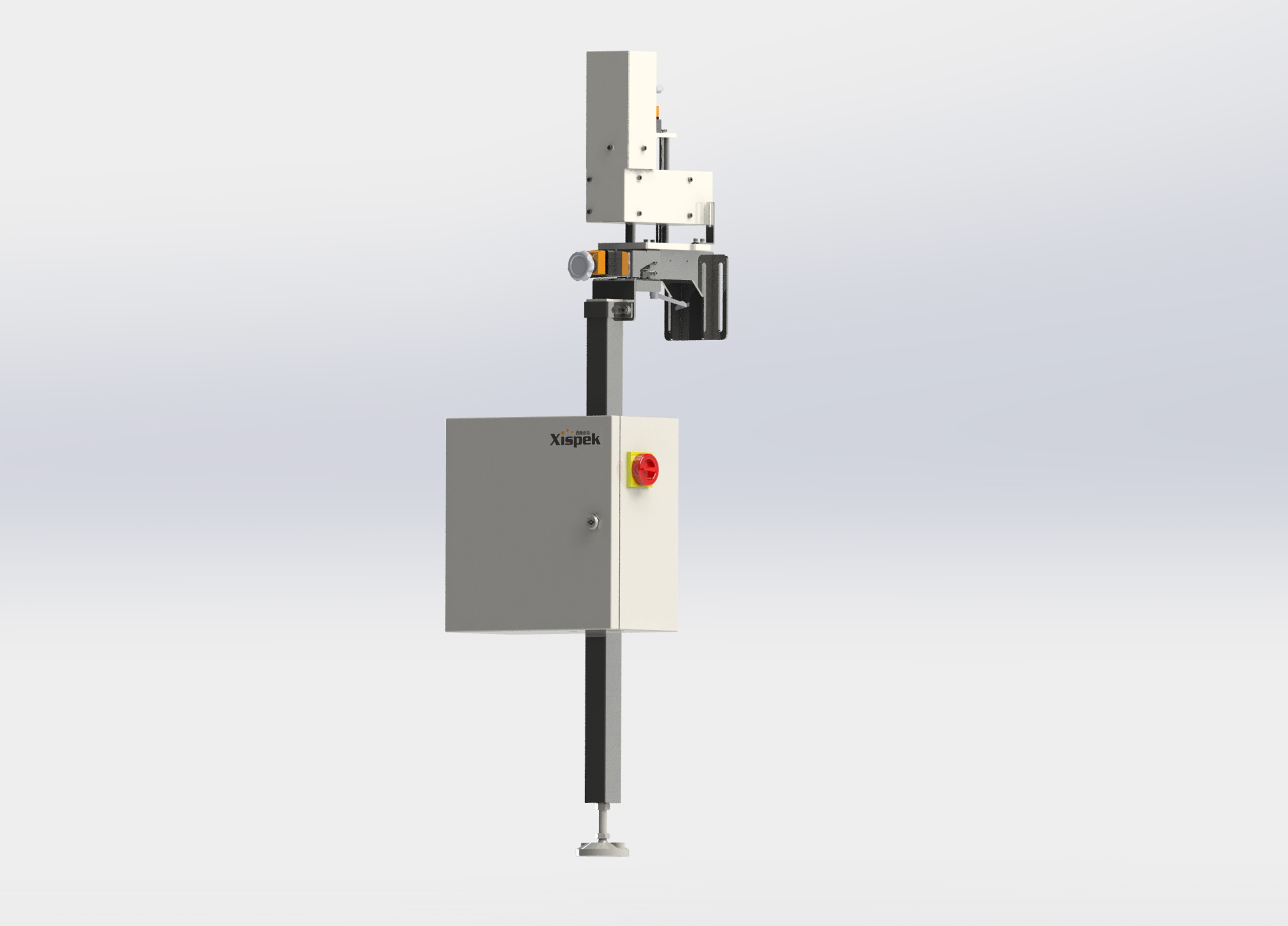

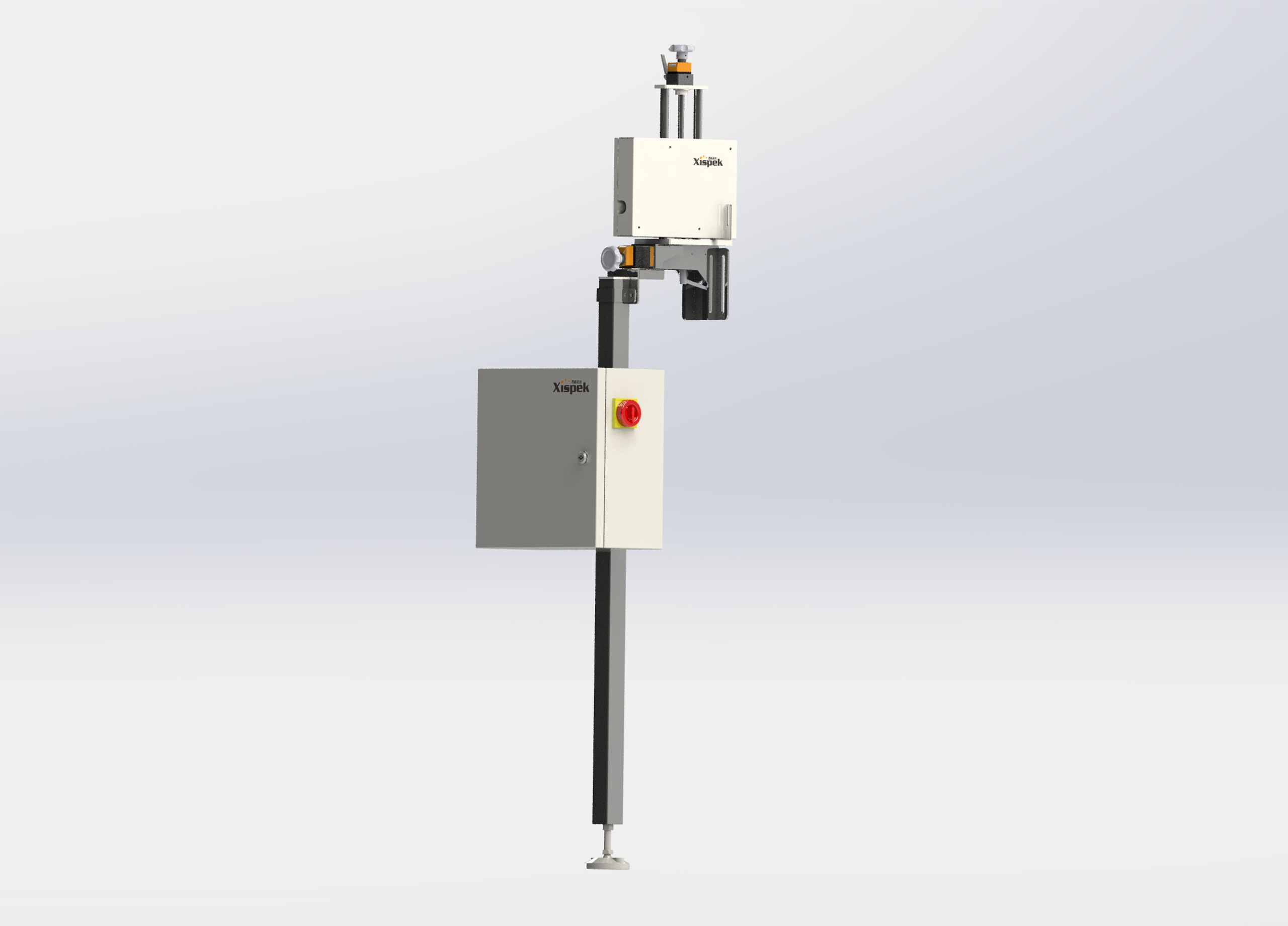

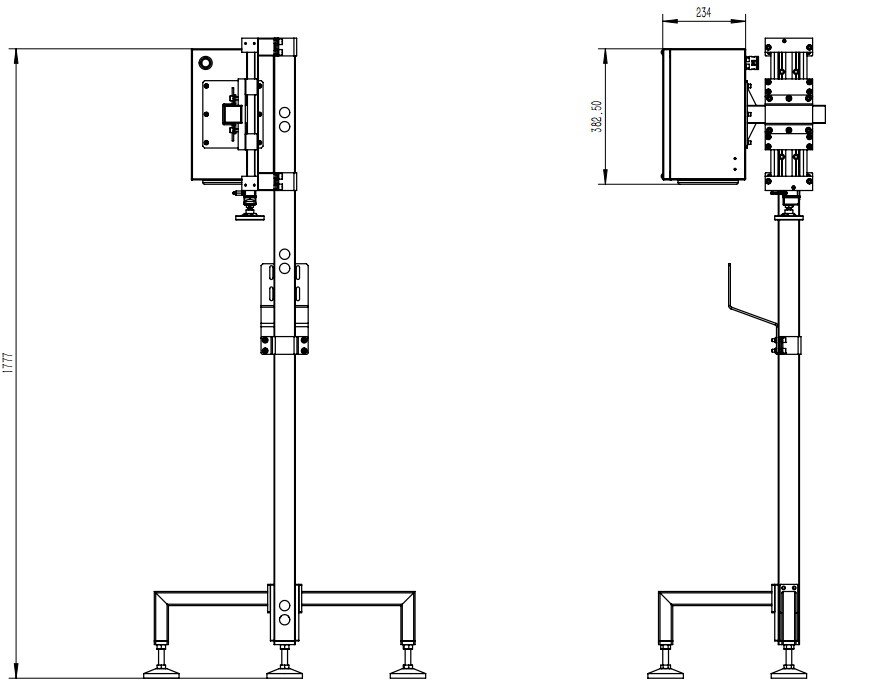

Can Bottom Code Inspector CDI is a reliable and stable inspection equipment. Different control centers can be selected according to actual production line speeds, achieving a maximum inspection speed of 90,000 cans/hour.

Viscodia is an inspection system designed for can production lines to inspect bottom codes. It accurately and efficiently identifies the presence/absence of codes, missing characters, and verifies dates and shift information, while rejecting defective products.

The bottom code inspection equipment uses different types of light sources depending on the code type. To achieve optimal inspection results, printed sample cans must be provided for setup.

Code presence

Code presence

Character missing

Character missing

Date recognition

Date recognition

Shift recognition

Shift recognition

Barcode, 2D code reading

Barcode, 2D code reading

OCR

OCR

|

|

| Missing code | Character missing |

High rotational tolerance for containers

High rotational tolerance for containers

Compatible with all types of coders - inkjet and laser marking systems

Compatible with all types of coders - inkjet and laser marking systems

Inspection module with IP65 protection level

Inspection module with IP65 protection level

Continuous alarm function prevents unnecessary stoppages and false rejects

Continuous alarm function prevents unnecessary stoppages and false rejects

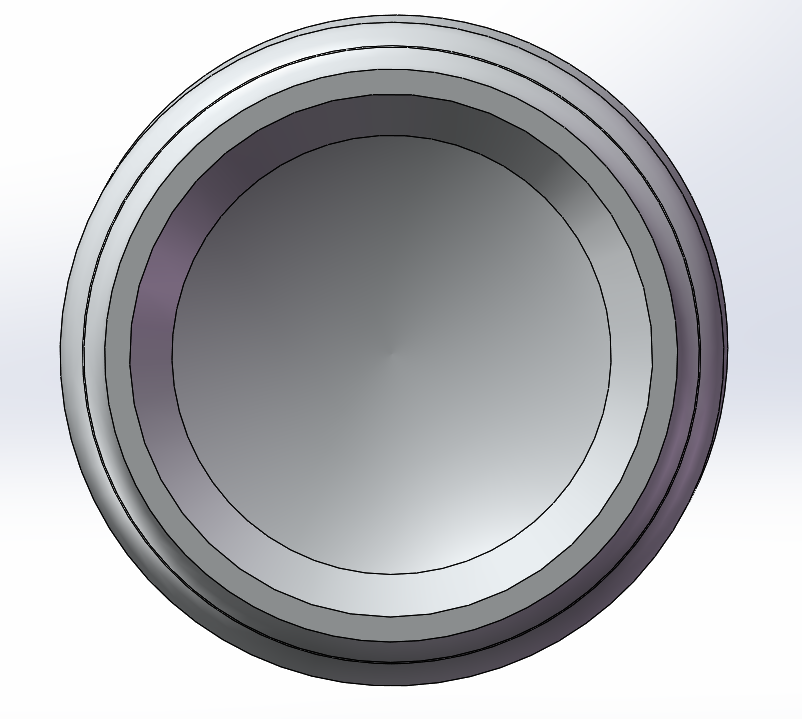

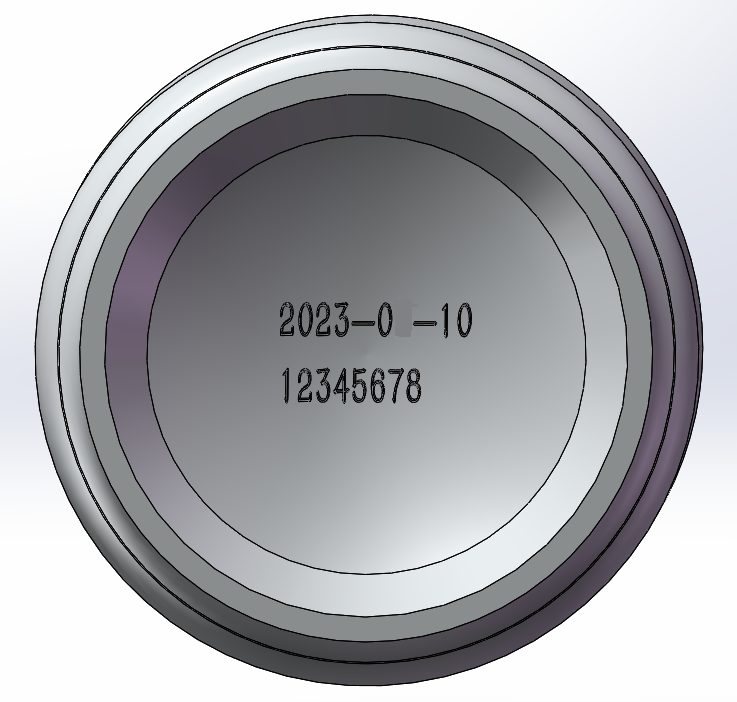

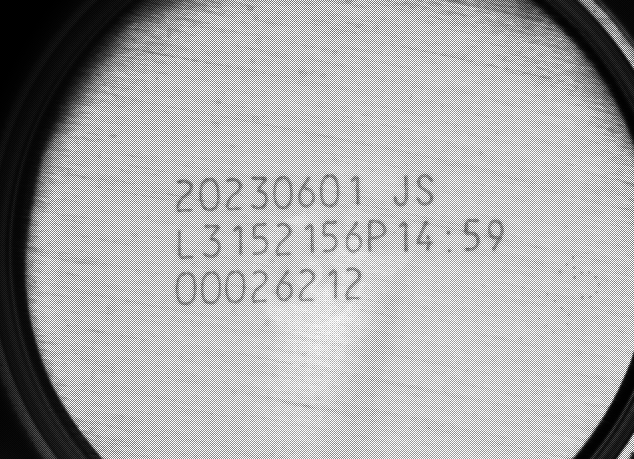

A good image is the beginning of a stable inspection, especially for can code inspection. Can code inspection needs to be customized according to the type of code and the material of the can and the shape of the bottom of the can with a specific light source and optical structure design, common difficulties are the bottom of the curved surface of the can, the bottom of the center of the can die number interference, print dot font and so on. Through the use of special light source can eliminate the reflective phenomenon caused by the bottom of the curved can, maximize the contrast and recognition of the background of the code and the bottom of the can. Can get a clear, uniform, small interference with the image, you can improve the accuracy of image processing and system stability. The following figure shows the four commonly used products of the coding of the actual picture.

|

|

|

Inkjet Coding |

Laser Coding |

Can code image processing is divided into five main steps:

Finding the center of the can base

Finding the center of the can base

Text background segmentation

Text background segmentation

Orientation recognition and correction

Orientation recognition and correction

Text segmentation

Text segmentation

Text verification

Text verification

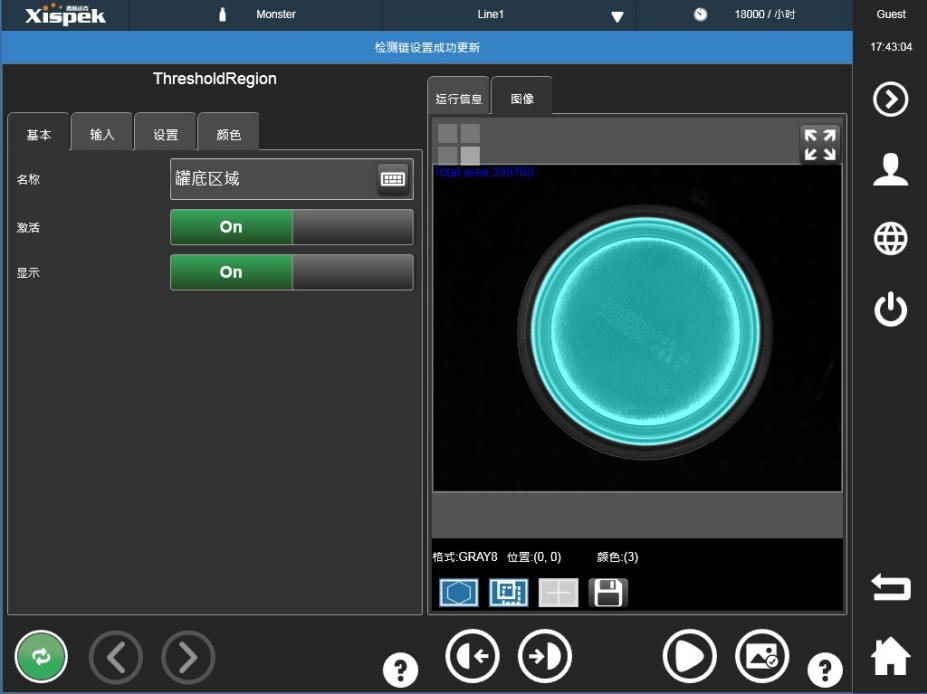

The following diagram illustrates the processing chain (can bottom code inspection image) utilizing XispVision® proprietary software

The first step of image processing is to accurately identify the location of the can bottom circle. Because find the location of the can bottom area to further confirm the coding area to be inspected,Subsequent image processing of the region of interest are based on the location of the center of the can bottom. On the production line, the captured image will certainly change. Through the stable find the center of the algorithm can completely ensure that as long as the image of the bottom of the can in the field of view, can accurately locate the bottom of the can and the position of the spray code, so as to lay the foundation for accurate identification.

In order to better recognize the text later, the text and the background need to be able to be completely differentiated. The whole bottom of the can has different illumination and gray scale. So we use a local adaptive binarization algorithm to intelligently separate the text from the background, as shown in Figure 2.4. The algorithm also adjusts the local contrast and sensitivity, so better results can be obtained even in the case of uneven illumination.

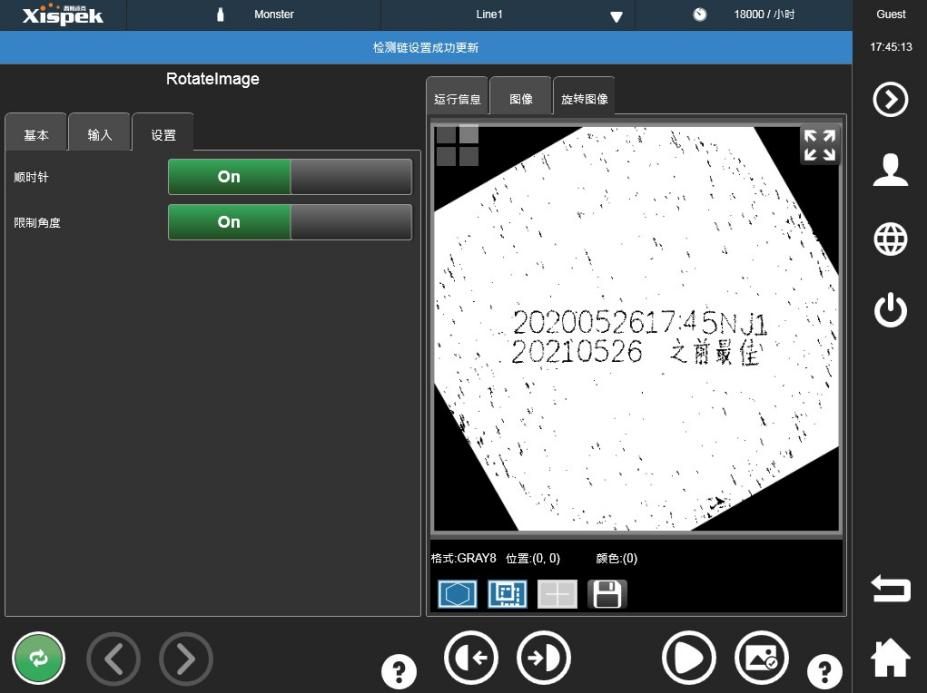

In the installation of the module should be installed as close as possible to the detection module in the printer, to prevent the cans to the detection point of substantial rotation. Even so, the position and angle of the can in the transmission process still has a certain degree of uncertainty. We are able to recognize the direction and angle of the text through the algorithm, and then rotate the text to the horizontal position, enough to ensure that the text rotation does not exceed ±30◦ in the case of the detection results are not affected at all.

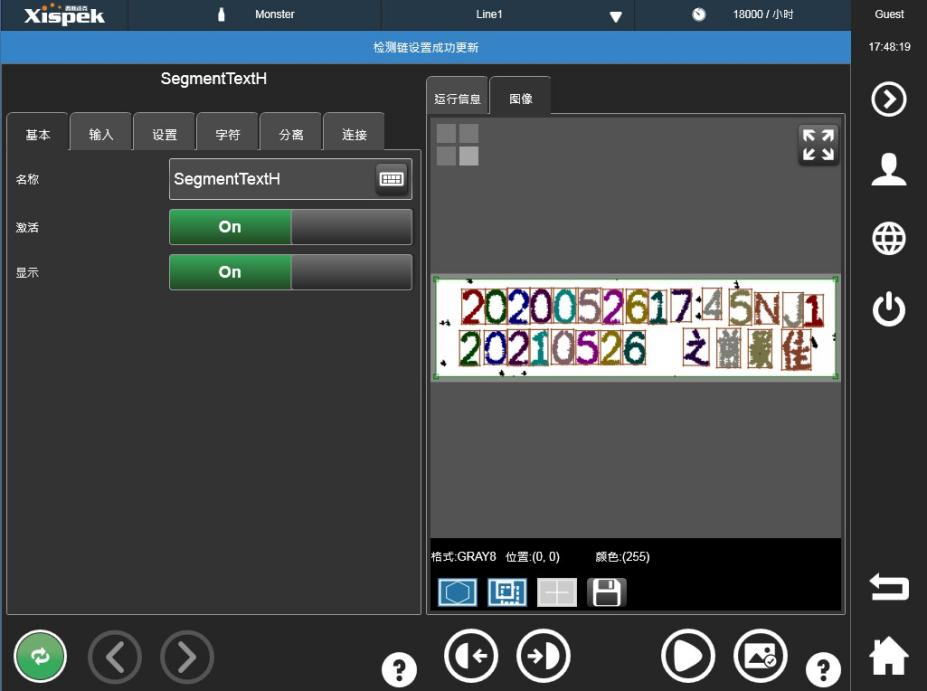

Text segmentation is to separate the text area, this process is crucial for the verification of the code, especially when OCR reading is required. After the text direction recognition and correction, the content of the code will be separated from each other again according to the width and height of the detected characters, to ensure that each character becomes an independent part, so as to facilitate the subsequent text verification of the code. For Monster Energy varieties, there may be aluminum cans metal material will produce a lot of grain noise, so in the segmentation process to join the algorithm through the regional algorithm and selection to suppress the noise.

After realizing the text segmentation, the quality of the spray code can be inspected and verified. The verification is divided into the following aspects:

No code

No code

Missing code

Missing code

missing lines

missing lines

Missing characters

Missing characters

OCR text read

OCR text read

Algorithms can evaluate the quality of the code by calculating features such as the number of characters, the area of the text, etc. XispVision® can even read the date of manufacture, the BBD and the batch. In practice, the OCR reading function is often combined with a continuous reject alarm to prevent too many false rejects.

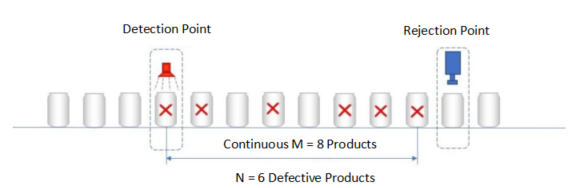

When the coding inspection system detects n incorrect coding data in m consecutive products, it triggers an alarm or reject command, where the values of m and n are set in the system according to the inspection and production conditions. For example, in the above figure, m is set to 8 and n is set to 6. When 6 or more defective products are detected in 8 consecutive products, an alarm will be triggered immediately to reject the signal.

The main advantage of continuous false alarms is:

1. Avoid production waste caused by date setting errors

2. Avoid unnecessary downtime and false rejects

3. Convenient setting, easy to use